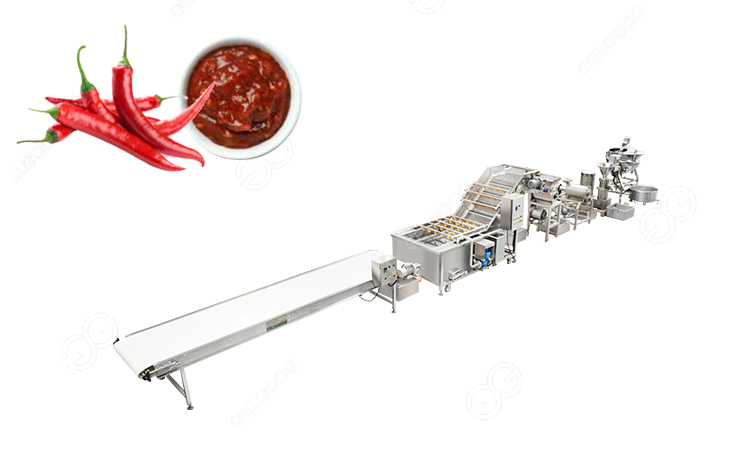

Hot sauce has become a staple condiment for many, and with the growing demand for unique and flavorful options, starting a hot sauce factory can be a lucrative venture. However, establishing a successful hot sauce production facility requires careful planning and the right equipment. In this article, we will explore what equipment do you need to make hot sauce in a factory setting.

Mixing and Blending Equipment:

Industrial Blenders: High-capacity blenders are essential for efficiently combining ingredients and achieving the desired consistency. Look for robust blenders with variable speed controls to handle different recipes and pepper varieties.

Kettles and Mixing Tanks: Large kettles and mixing tanks are crucial for cooking and blending ingredients. Stainless steel tanks are preferred for their durability and ease of cleaning.

Heating and Cooking Equipment: Steam Jacketed Kettles: These kettles use steam to heat the sauce evenly and prevent scorching. They are available in various sizes to accommodate different batch sizes.

Cooking Vats: Industrial-sized cooking vats are suitable for large-scale production. They allow precise temperature control during the cooking process.

Filling and Packaging Machinery:

Filling Machine: Automated filling machines ensure accurate and consistent quantities of hot sauce are dispensed into bottles. Piston fillers and gravity fillers are commonly used in sauce production.

Labeling Machines: Efficient labeling is crucial for brand identity. Labeling machines streamline the process and ensure that each bottle is properly and uniformly labeled.

Bottling and Capping Equipment: These systems transport bottles between different stages of the production line, facilitating a smooth and continuous process.

Capping Machines: Ensure a secure seal with automated capping machines. Choose models compatible with various cap types and sizes.

Quality Control and Testing Equipment:

Viscosity Measurement Tools: Consistency is key in hot sauce production. Viscosity meters help maintain the desired thickness and texture.

pH Meters: Monitoring the pH level is essential for both flavor and safety. pH meters aid in ensuring the acidity of the hot sauce falls within the desired range.

Packaging Equipment:

Case Packers and Sealers: Automated case packing systems enhance efficiency by quickly and accurately packing finished products into cases.

Palletizing Equipment: Streamline the final stage of packaging with palletizing equipment, which stacks cases for easy transport.

Starting a hot sauce factory requires a significant investment in the right equipment to ensure efficient production and maintain product quality. By investing in reliable and high-capacity hot sauce making machinery, adhering to industry regulations, and implementing strict quality control measures, aspiring hot sauce manufacturers can create a successful and sustainable business in the competitive condiment market.