Description

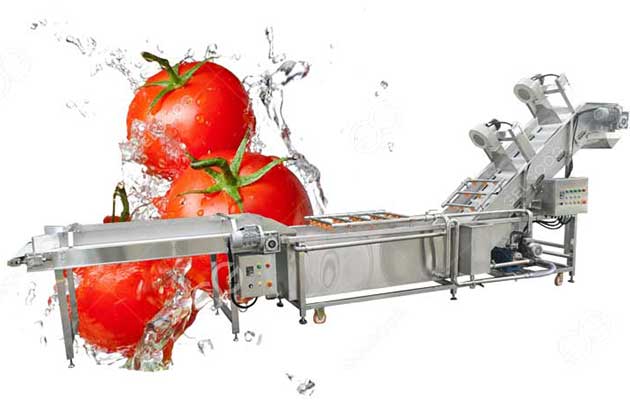

The tomato blanching machine is an essential equipment for tomato peeling. It softens the fresh tomatoes through hot water pre-cooking, and can retain the original color of the tomato, and is transported to the next process through a mesh belt for processing.

The water bath blanching function can effectively mix the tomatoes in the medium water in a balanced manner, providing a pre-cooking effect on the tomatoes, effectively controlling the blanching time of the tomatoes, and completing the blanching process of the tomatoes qualified.

Tomato Blanching Machine Features:

1. Production capacity: 500kg/h-1500kg/h

2. The speed is adjustable and adopts stepless speed regulation.

3. The blanching temperature is controlled automatically within the range of 80~95℃.

4. Steam consumption: 0.5T/h×0.5Mpa per ton of blanching product.

5. The cylinder of the blanching machine can be made into an insulation layer according to customer requirements, so that it can be operated by personnel.

6. The production line is arranged in a “one” shape, or it can be arranged in an “L” shape.

7. It is made of stainless steel SUS304 material, which fully meets the food hygiene standards of the products.

Technical parameters of tomato blanching

The blanching machine is a pre-cooking equipment often needed in the color protection process of tomato processing. The blanching mechanism stops the enzyme activity in the tomato to maintain the unique fresh color of the tomato, emit the green smell of the tomato and retain the fragrance, and enhance the cell The softness of it is conducive to the evaporation of water and lays a good foundation for the process requirements of the next peeling process.

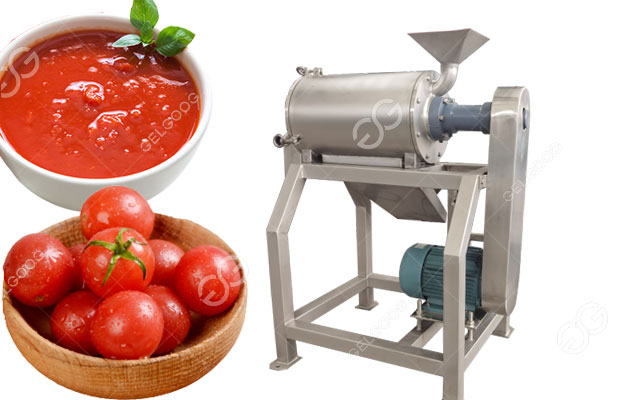

After the tomatoes are blanched, they are transported by the mesh belt and dropped into the flat roller brush peeling machine. Driven by the motor, the hair roller rolls in a relatively reverse direction, and directly touches the tomato softened by blanching to produce friction to achieve the peeling effect.

Tomato Brush Peeling Machine Features

1. The body is made of 304 stainless steel, which is corrosion-resistant, rust-proof and easy to clean;

2. Waterproof button controller, safe and reliable;

3. The conveying speed can be adjusted;

4. The distance between the brush rollers can be adjusted;

Most bacteria, yeasts and molds are difficult to remove from the food surface. Washing fresh food will only slightly reduce their number. Peeled root crops, underground stem crops and tomatoes have greatly reduced their numbers.

By removing the tomato skin that contains a lot of bacteria to reduce the bacterial load, we can get a complete, safe and hygienic peeled tomato.

In addition, we also provide tin can packaging equipment for peeled whole tomatoes, which can ensure that the peeled tomatoes will not breed new bacteria during transportation and extend their shelf life.

Reviews

There are no reviews yet.