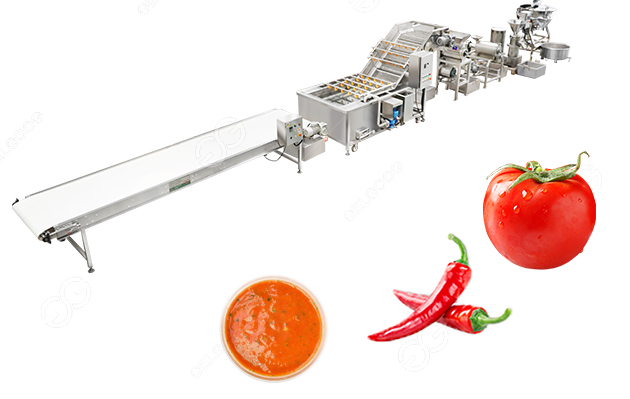

Description

The salsa sauce production line is a highly automated system of equipment designed for the efficient production of salsa sauce. The tomato chili sauce making machine is capable of meeting the production needs of enterprises of different sizes, with capacity ranging from 300 kg/h to 1,000 kg/h. The entire production process includes picking, cleaning, crushing, grinding, mixing and cooking, filling and sterilizing to ensure high quality and hygienic safety.

Salsa Sauce Production Process:

- Picking

The first step in the production process is picking. The chili enter the sorting machine through the conveyor belt, and the raw materials that do not meet the requirements are manually removed to ensure that the chili entering the next process are fresh and free of impurities.

- Cleaning

The picked chili enter the cleaning equipment. The cleaning equipment uses a combination of high-pressure water flow and brushes to thoroughly clean the chili, remove surface soil and pesticide residues, and ensure the cleanliness of the chili.

- Crushing

The cleaned chili enter the crusher through a conveyor belt. The crusher preliminarily crushes the chili to a particle size suitable for grinding into sauce. The crushing process is efficient and uniform, providing a good foundation for the subsequent sauce grinding process.

- Grinding

The crushed chili enter the sauce grinding machine for fine grinding. The machine uses advanced grinding technology to grind the chili into a uniform fine sauce, ensuring the delicate taste of the sweet and spicy sauce.

- Mixingand cooking

The ground sauce goes into the mixing and cooking tank. During the preparation process, add sugar, salt, tomatoes, garlic, onions and other seasonings, and stir evenly. The cooking process is controlled within a certain temperature and time range to ensure that the taste and flavor of the tomato chili sauce are at its best. At the same time, high-temperature sterilization is used to extend the shelf life of the tomato chili sauce.

- Filling

The cooked salsa sauce enters the filling machine through the conveying system. The filling machine uses precise filling technology to ensure that the capacity of each bottle of salsa sauce is consistent. The filling process is fully enclosed to avoid secondary pollution and ensure product hygiene.

- Sterilize

After filling, the salsa sauce bottles enter the sterilization machine for final sterilization. The sterilizer uses high-temperature steam or ultraviolet sterilization technology to completely kill microorganisms that may be present in the bottle to ensure the safety and stability of the salsa sauce.

Advantages of Salsa Sauce Production Line:

Efficient production: high degree of automation of the production line can significantly improve production efficiency and reduce labor costs.

High product quality: multiple processes ensure the taste, color and flavor of the salsa sauce to meet the market demand.

Safe and hygienic: the whole production process meets the food safety standards, ensuring that the products are pollution-free, safe and hygienic.

Easy to operate: the equipment is easy to operate, easy to maintain, and the layout of the salsa sauce production line is reasonable and adaptable.

Scope of application

The tomato chili sauce making machine is widely used in all kinds of food processing enterprises, especially in larger-scale condiment production plants. Its flexible capacity range enables it to meet different production requirements, and it is the ideal choice for improving production efficiency and product quality.

Reviews

There are no reviews yet.