Description

This salad processing line mainly include vertex vegetable salad leaves washing machine,cutting machine,drying machine,and packaging machine.It can process 500kg salad leaves per hour!!

How To Make A Salad Process

The salad processing line mainly process include salad leaves picking,cutting,washing,drying,packaging process.Each salad making process correspond to one equipment.Here are the details introduction of each machine.

Salad Chopper Machine

Before washing the salad,we need to chopping the salad leaves into shreds,this salad chopper machine is multi-purpose, it can cut vegetable leaves and root vegetables, and can slice, wire, strip, dice, segment, shred and other rhizomes. The shape of the finished product: slice, square wire strip, dice, diagonal slice.

The whole machine is made of high-quality stainless steel, conforms to national and food standards, and fully adapts to various complex environments. Thoughtful design, reasonable structure and long machine life.

After chopping the salad leaves ,then you can use the salad washing machine to wash the salald shreds.

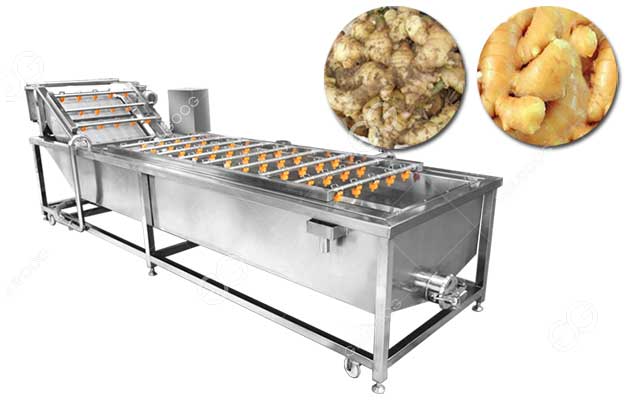

Vortex Vegetable Salad Leaves Washing Machine

The vortex vegetable salad leaves washing machine adopts bubble water bath cleaning, which is specially designed for vegetable salad leaves cleaning. It is made of high-quality stainless steel and meets food hygiene standards. It is equipped with a bubble generating device to make the vegetables in a tumbling state, removing silt, dust and surface pesticides.

Salad Leaves Washing Machine Features

1. Save water, electricity, time, cleanliness and sanitation.

2. No damage to vegetables, high efficiency, small footprint and reliable operation.

3. The installation is simple, the operation is simple, the maintenance is convenient, and the reach is low.

Scope of Salad Maker Machine Application

The vortex cleaning machine is mainly used for the cleaning of vegetables. It is specially suitable for leafy fruits and vegetables growing in the soil such as lettuce,spiniach,cabbage,moringa leaves ,herb ect. It has high cleaning degree and can maintain the color.

Salad Making Machine Advantage

The product is made of stainless steel, strong and durable, and the equipment raw materials will not be damaged, so as to achieve the effects of high cleaning, labor saving, water saving, stable equipment and reliability. .

This machine uses high-pressure water flow and bubble generating device to hit the surface of vegetables. The energy generated by the bursting of bubbles when in contact with the vegetable salad is used to scrub the surface of the cleaned vegetable salad, and the cleaned vegetable salad is cleaned.

The high-pressure water flow makes the material in a tumbling state, removing the pesticide residue on the surface of the vegetable salad. The floating objects in the vegetable washing machine can overflow from the overflow tank, and the sediment is discharged from the mouth to achieve the purpose of cleaning.

On the basis of traditional swirling cleaning, a bubble cleaning design is added, and a high-pressure gas injection pipe is arranged at the bottom of the cylinder to eliminate the clumping phenomenon that occurs when the traditional swirling vegetable washer cuts and cuts vegetable salad during cleaning;

The bubble shock wave principle can clean the surface of vegetables and fruits, improve work efficiency by more than 50%, effectively kill harmful bacteria, and decompose residual pesticides;

Vertical cleaning + 16 high-pressure and high-pressure bubble vibration cleaning, double clean cleaning, whether it is whole vegetables or cut vegetables, broken vegetables, eddy current vegetable washing machine can easily handle

During the working process, the medium water is pumped into the main tank through the circulating water pump to realize the recycling of water, which saves energy and is environmentally friendly and sanitary. The upper spray pipe of the lifting part is always transported, so that the water in the tank is always transported. The sewage is replaced.

This machine is equipped with a cutting board next to the wall, which effectively separates the washed vegetables from the washed sediment, reduces the turbidity of the water, and significantly improves the recycling rate of the washing water. It can save 80% of the washing water and save manpower;

After washing the salad shreds,you may also want to packaging them,so you need to drying the salad shreds surface water,then to packaging them.So you can sold them in your locally supermarket!

Salad Packaging Machinery

1. The whole salad packaging machine has advanced design, reasonable structure, convenient adjustment, operation and maintenance;

2. Servo film transport system positioning standard; synchronous belt transport film, stable and reliable;

3. Automatic correction function, saving time and film, improving the reliability and intelligence of the whole machine

4. Equipped with a variety of automatic alarm protection functions to minimize loss;

5. This machine is matched with a metering device to automatically complete product metering, feeding, filling and bag making, date printing, inflation (exhaust),

If you have your own vegetable farm, or you are engaged in vegetable sales and want to expand your business scope and increase the added value of your fruit and vegetable business, then this set of saald processing line is very suitable for you to invest, and it will bring you greater income! If you have any questions about salad processing, please feel free to leave a message with us online!

Reviews

There are no reviews yet.