Red chilli sauce is a staple condiment in many kitchens worldwide, known for its fiery flavor and versatility. Have you ever wondered about the journey this beloved sauce takes from farm to table? Let’s delve into red chilli sauce manufacturing process.

Sourcing the finest red chillies:

The journey begins with the careful selection of premium quality red chillies. These chillies are sourced from local farms or sometimes imported from regions renowned for their spicy produce. The ideal chillies for sauce production are typically ripe, vibrant red in color, and possess the perfect balance of heat and flavor.

Cleaning and sorting:

Once the red chillies arrive at the factory, they undergo a thorough cleaning process to remove any dirt, debris, or impurities. After cleaning, the chillies are sorted based on size, color, and quality. This ensures consistency in the final product and eliminates any undesirable elements.

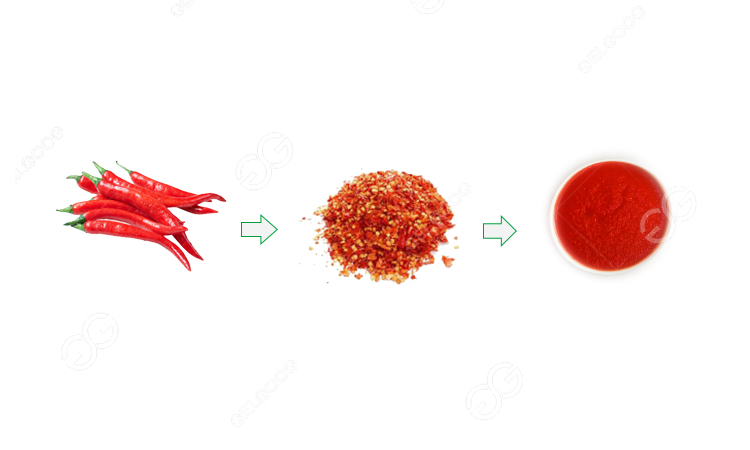

Grinding and blending:

The cleaned and sorted red chillies are then fed into industrial-grade grinding machines. These machines finely grind the chillies into a smooth paste or puree, extracting their intense flavor and heat. Depending on the desired consistency and flavor profile, other ingredients such as garlic, vinegar, salt, and sugar may be added at this stage. The precise blending of ingredients is crucial to achieving the perfect balance of flavors in the sauce.

Cooking and reduction:

Next, the chilli paste undergoes a cooking process in large stainless steel vats or kettles. During cooking, the mixture is heated to a specific temperature to enhance the flavors and ensure food safety by eliminating any harmful bacteria. Additionally, the sauce undergoes a reduction process, where excess moisture is evaporated, resulting in a thicker and more concentrated sauce.

Straining and homogenizing:

After cooking, the sauce is strained to remove any remaining solids or seeds, resulting in a smooth and uniform texture. To achieve consistency throughout each batch, the sauce may undergo homogenization, a process that breaks down fat globules and ensures even distribution of ingredients.

Packaging and bottling:

Once the sauce reaches its desired consistency and flavor, it is ready for packaging. The hot sauce is carefully pumped into sterile bottles or jars, which are then sealed to maintain freshness and prevent contamination. Labels containing product information, ingredients, and branding are applied to the bottles before they are packaged into cases for distribution.

Quality control and testing:

Throughout the manufacturing process, rigorous quality control measures are in place to ensure that the red chilli sauce meets the highest standards of quality, taste, and safety. Samples from each batch are tested for consistency, flavor, ph levels, and microbiological contamination to guarantee a superior product.

From the fields where red chillies are grown to the state-of-the-art factories where they are transformed into delicious sauce, the manufacturing process of red chilli sauce is a blend of artistry and science. Each step, from sourcing the finest ingredients to stringent quality control measures, contributes to the creation of a product cherished by spice enthusiasts worldwide. If you also want to start chili sauce business, contact us, we can supply you the chili sauce production line.