Description

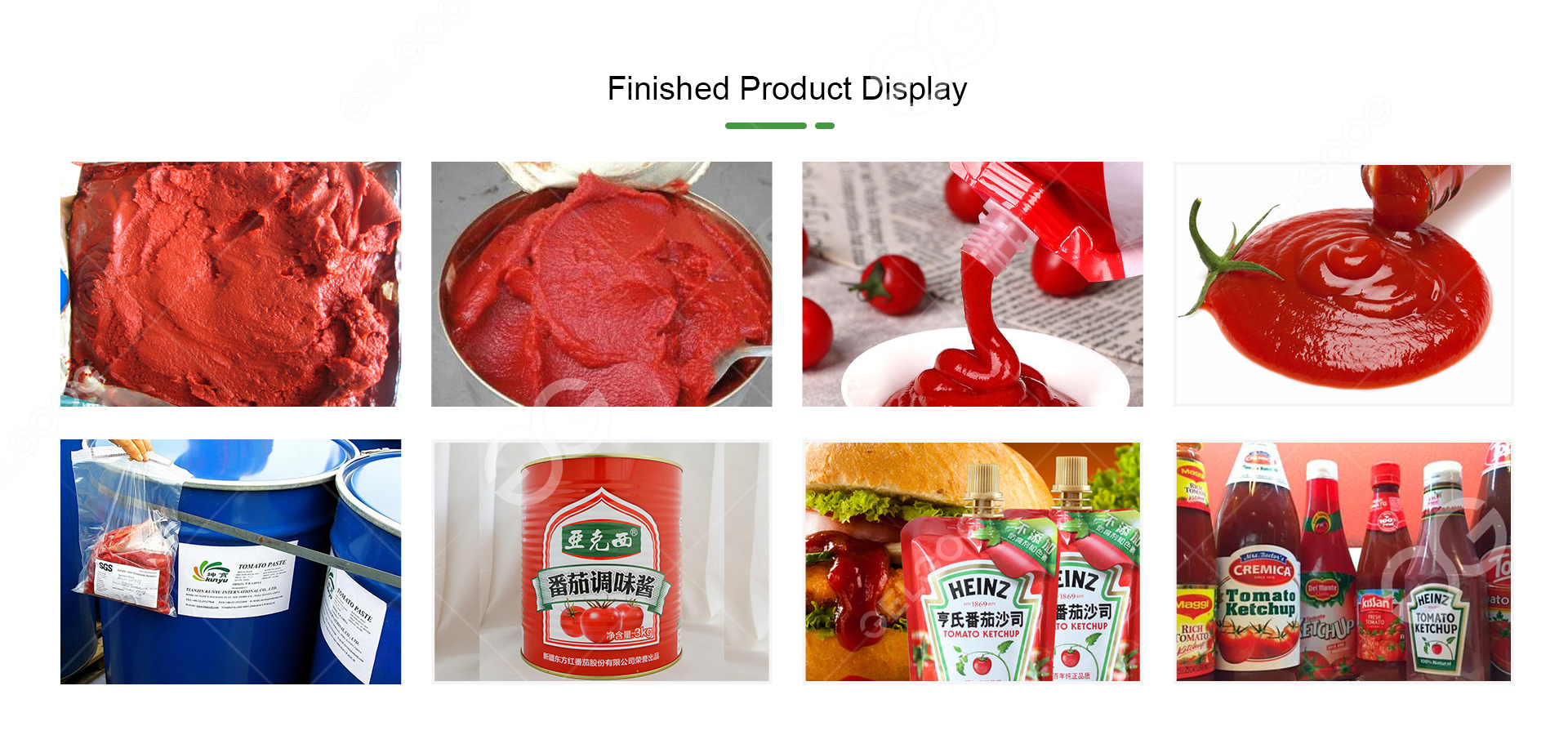

The small scale tomato processing plant is suitable for 30% brix tomato paste concentrate products with 250 kg/h yield. It uses ripe red tomatoes as raw materials and is made through crushing, pulping,concentration, filling, and sterilization.

Mini Tomato Paste Production Line Parameter:

1. Raw material: Fresh tomato

2. Final products. Tomato sauce and ketchup(Mixed with itric acid,starch and sugar)

3. Brix:28-30%

4. Input: 5% brix in fresh tomato, there needs 1500kg/h fresh tomato

5. Output: 250 kg/h concentrated tomato paste with 30% brix

6. Packing method:Sachet packing , PET packing

7. Semi automatic production line

Tomato Paste Processing Machine Working Flow:

Tomato→Bubble Washing→Crushing→Pulp Making→Storage Tank → Screw Pump→Concentrating and mixing→Screw pump→Paste Filling→Sterilization.All the above processes correspond to a specific device:

Tomato washing machine:Under pressure of air bubble and water pressure to clean those tomatoes.

The tomato washing machine is also called tomato floating machine,this washing machine is specially designed for tomato.It have two layer ,the first layer we attitude the ttraditional mesh belt with stainless steel fence tube.The ingenious double-layer design makes the sand and gravel settle to the bottom layer and drain away.

Crushing machine:To crush tomatoes for the preparation of pulp making;

Before we make the tomato pulp,we need to crushing the tomato or even need to cutting the tomato before crushing.On the one hand the crushed tomato will be smoother feeding for the next pulp making process;On the other hand, if you the crushing tomato will greatly improve the tomato pulp yield!

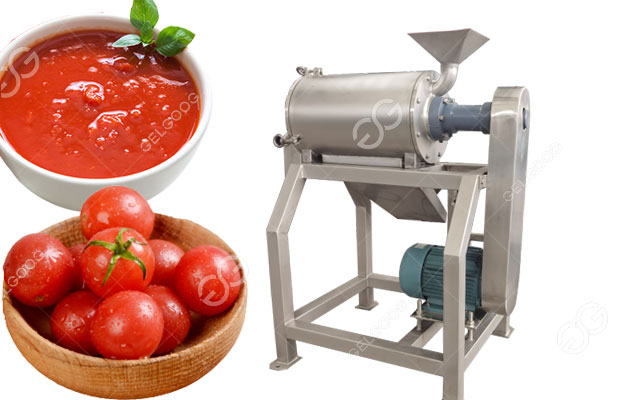

Pulp making machine: The machine in the form of single-channel, automatic separation of tomato pulp and residue;

The tomato pulp machine is mainly used for beating and peeling the berries such as tomatoes after cutting and crushing, so that the pulp and juice are separated from other parts, which is convenient for the concentration of the juice and the completion of other subsequent processes.

Temporary storage tank:The tank is made of high-quality SUS304 stainless steel is used for stroage the tomato pulp temporarily;

Cooking Pot:Used to concentrate tomato pulp, evaporate excess water;

The tomato paste cooking pot have both sterilization and concentrate functions.It is mutifunctional and economy.You can set different cooking time for different final products(Ketchup,tomato sauce ,tomato paste,tomato puree).The longer cooking time you set,the less water content in the final products.

Tomato paste filling machine:Filling tomato sauce/ketchup into

different size of bottles.

The semi-automatic filling machine has reasonable design, compact model and convenient operation. The filling volume and filling speed can be adjusted at will, the filling speed is fast, and the humanized design is more in line with the requirements of modern enterprises.

Pressurization Machine:Pasteurize the sachet in 80 degree water.

Small Scale Tomato Processing Plant Advantages:

1. Small Scale Tomato Processing Plant installation and positioning are designed and arranged according to the size and characteristics of the plant to ensure the rationality of on-site construction and operation.

2. The design concept of energy saving and emission reduction is more than 20% energy saving than equipment in the same industry.

3. The unique process design and pipeline connection arrangement preserve the original natural aroma components of tomatoes.

4. Fully automatic control system, automatic fault alarm system, and comprehensive safety guarantee mechanism to ensure the safety of equipment and personnel.

Reviews

There are no reviews yet.