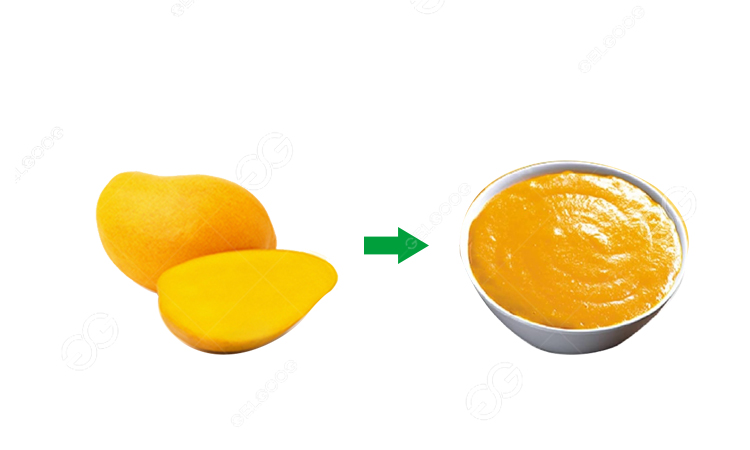

Mango pulp is a popular ingredient in various food products, including beverages, jams, ice creams, and sauces. To meet the growing demand for mango pulp, many food processing companies invest in efficient mango pulp processing lines. These processing lines are designed to handle the entire process of converting fresh mangoes into pulp, ensuring quality and consistency in the final product. In this article, we will delve into the factors that contribute to the cost of setting up a mango pulp processing line.

Capacity and scale:

The processing capacity of the mango pulp line is a critical factor influencing its cost. Larger processing lines with higher capacities generally require more advanced machinery and infrastructure, leading to increased costs. Smaller processing lines may be more affordable but may not be suitable for companies with higher production requirements.

Machinery and equipment:

The cost of machinery and equipment is a significant component of the overall investment. This includes mango washing machines, peeling machines, pulping machines, and sterilization equipment. The level of automation and technological sophistication of these machines can vary, impacting their cost.

Material handling systems:

Efficient material handling systems, such as conveyors and elevators, are essential for the smooth flow of mangoes through the processing line. The choice of material handling equipment can affect the overall efficiency of the processing line and, consequently, its cost.

Quality control and testing equipment:

Quality control is crucial in the food processing industry. Investing in equipment for quality testing and control, such as sorting machines and laboratory instruments, adds to the overall cost. These tools ensure that the final product meets the required standards and regulations.

Processing line layout and infrastructure:

The layout and design of the processing line influence the efficiency of operations. Costs associated with the construction of processing facilities, utilities, and infrastructure should be considered. A well-designed layout can optimize workflow and reduce operational costs in the long run.

Energy consumption and sustainability:

The energy efficiency of the processing line can impact both operational costs and environmental sustainability. Investing in energy-efficient equipment and practices may incur higher upfront costs but can lead to long-term savings and a reduced environmental footprint.

Installation and training:

The cost of installation and training personnel to operate and maintain the processing line is often overlooked. Adequate training ensures that the machinery is used efficiently, minimizing downtime and potential errors.

Regulatory compliance and certification:

Meeting regulatory standards and obtaining certifications for food safety and quality assurance can add to the overall cost. Compliance with international standards is crucial for exporting mango pulp to different markets.

Maintenance and service contracts:

Regular maintenance is essential for the longevity and optimal performance of the processing line. Companies should factor in the cost of maintenance and consider service contracts with equipment manufacturers to address unforeseen issues promptly.

Market conditions and supplier selection:

The cost of the processing line can also be influenced by market conditions and the selection of suppliers. Engaging with reputable suppliers may involve higher initial costs, but it can contribute to the reliability and durability of the equipment.

Investing in a mango pulp processing line requires careful consideration of various factors, and the associated costs can vary based on the scale, technology, and quality standards. While the initial investment may seem significant, a well-designed and efficient processing line can lead to increased productivity, reduced operational costs, and a competitive edge in the market. Companies should conduct a thorough feasibility study and assess their specific production requirements before making decisions about setting up a mango pulp processing line.