Description

As consumers’ demand for natural fruit juice drinks continues to grow, mango juice is increasingly favored by the market for its sweet and rich taste and rich nutritional value. In order to meet the needs of juice processing companies for efficient, automated and safe production, our company has developed and launched a mango juice processing line. The production line adopts modern process flow and is equipped with high-performance core equipment. It has many advantages such as high production capacity, high quality and customization. This mango juice processing line is an ideal choice for mango juice processing companies to increase production capacity and product competitiveness.

Production Capacity And Customized Services

This mango juice processing line has a designed capacity of 1000 kg/H, which is suitable for the daily needs of medium-sized mango juice production companies. According to the customer’s process requirements and actual production targets, our company can provide a variety of capacity specifications ranging from 500kg/H to 5000kg/H, achieving flexible customization to meet the needs of different production scales.

Mango Juice Production Process:

- Cleaning: Bubble cleaning is used to effectively remove mud, impurities and agricultural residues on the surface of mangoes, ensuring the hygiene and safety of subsequent processing.

- Blanching: Through short-term heat treatment, the enzyme activity in mangoes is passivated to prevent oxidation and discoloration, while softening the flesh to facilitate pitting and pulping.

- De-pitting and pulping: effectively separate the mango pulp from the pit, and further crush the pulp to form a uniform pulp.

- Homogenization: high-pressure homogenization of mango pulp to improve the stability and taste of the juice and prevent stratification and precipitation.

- Degassing: remove the dissolved air in the mango pulp through the vacuum degassing system to prevent oxidation, improve taste and extend shelf life.

- Sterilization: Ultra-high temperature (UHT) sterilization technology is used to effectively kill microorganisms in a short time and retain nutrition and flavor.

- Aseptic filling: Filling into containers in a sterile environment ensures that the product is sterile, safe, and has a long shelf life.

Core Equipment of Mango Juice Processing Plant:

☆ Bubble cleaning machine: uses circulating water spray to clean thoroughly without damaging the peel, suitable for all kinds of fresh fruits.

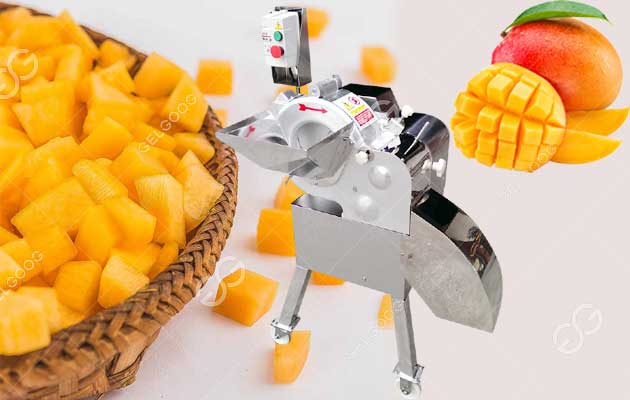

☆ Pit removal and pulping machine: combines pit removal and pulping in one, with compact structure and high efficiency. The processed mango pulp is fine and uniform, with an output of 100kg/h-2000kg/h.

☆ Aseptic filling machine: It adopts fully enclosed aseptic filling technology to avoid secondary contamination and is widely used in various packaging forms such as glass bottles, PET bottles, and aseptic bags.

Mango Juice Processing Plant Features:

- High degree of automation: The mango juice production line can realize PLC centralized control, reduce manual operation, and improve production efficiency and consistency.

- Sanitary and safety guarantee: All parts in contact with mangoes are made of food-grade stainless steel (SUS304/316L), which complies with GMP and HACCP standards, is easy to clean and corrosion-resistant.

- Easy to operate and maintain: The equipment structure is reasonably designed to facilitate daily maintenance and cleaning.

Quality Assurance:

The company guarantees that the mango juice processing plant provided is brand new, unused, made of the latest design and suitable materials, and meets the quality, specifications and performance specified in the contract in all aspects. The quality assurance period is 12 months after the production line is accepted (except for human-caused reasons and wearing parts).

Reviews

There are no reviews yet.