To make durian into puree in Malaysia, the durian needs to be peeled first. Put the durian pulp into the durian puree extraction machine, it can automatically separate the durian pulp from the core, and mash the separated durian pulp into a puree.

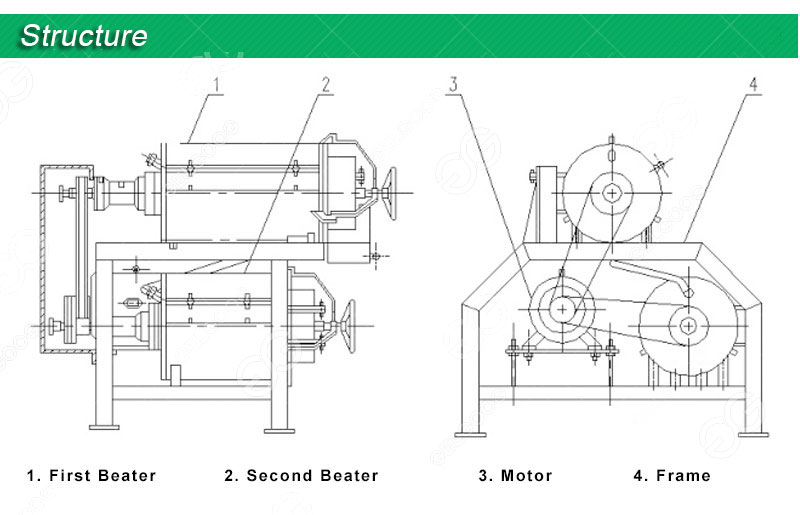

Durian Puree Extraction Machine

A. Cylindrical screen: Use a stainless steel plate of 0.35~1.20mm thickness to pounch and bend the cylinder body into a circle

Weld after round, with reinforcement rings welded on both sides;

Or two semi-circular bodies are connected by screws to form a cylinder, which is installed horizontally inside the casing.

B. Shaft: It has two scrapers to move the material to the broken blade, screw propeller, and scrape the material;

The scraper connect with the holder on the shaft by bolts, and the adjustment bolt can adjust the distance between the scraper and the screen wall;

It is installed symmetrically on the side of shaft C, and has an included angle with the shaft warp-lead angle.

C. Lower hopper, collecting funnel, frame and transmission system.

We all know that durians are abundant in Malaysia, and they only have a storage period of about two days when they are picked from the tree. It is difficult to sell them all over the world and the cost is high. Therefore, in the durian season in June and July every year, the local price of durian is very cheap, but if the durian is made into mud, it will have many uses, and the market value is naturally much higher than that of durian as a fruit.

How to make durian puree?

The motor is driven by a belt to make the scraper mounted on the spline rotate at high speed.

When the crushed durian enters the machine through the inlet, the pulper will evenly discharge the durian to the scraper and screen.

Due to the rotation of the scraper and the existence of the lead angle, the durian moves along the cylinder to the outlet end, and the moving track is spiral.

The durian is rubbed by centrifugal force during the movement between the scraper and the screen cylinder.

Broken, puree and meat (have become pulp) are sent to the next process through the sieve, (the double-pass beater repeats the above process), the skin and seeds are discharged from the slag hopper to achieve automatic separation purpose.

As long as the screens of different specifications are changed and the lead angle of the scraper is adjusted, different beating speeds can be changed to obtain satisfactory results.