Description

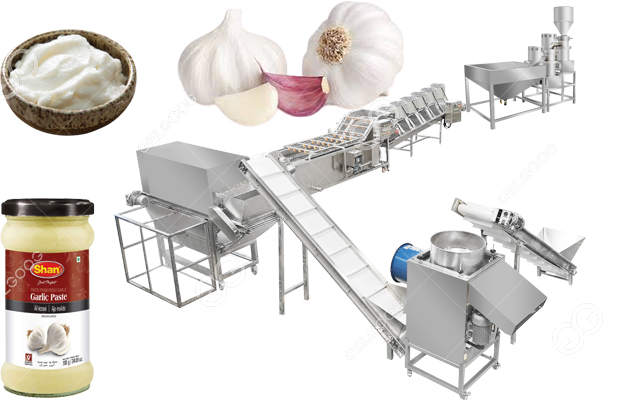

The garlic paste making machine can automatically process the garlic bulbs into garlic cloves ,grinding the garlic cloves into 100% without additives garlic paste. After get the garlic paste you can add oil, water ,lemon juice ,salt ect flavoring according to your preference for the taste of the final product.

A compale garlic paste making machine mainly include garlic bulbs seperating, peeling , washing , air drying , grinding , mixing , and filling process.There are elevating equipment, pumps, and pipes in the middle to make connections.

Garlic Paste Making Machine Advantages

▼No pollutant discharge, more environmentally friendly;

▼Washing water can be recycled to save water resources;

▼High degree of automation, saving time and effort;

▼Food-grade stainless steel material, safe and healthy;

How To Make Garlic Sauce Paste?

Garlic separating machine

The garlic clove separating machine uses a built-in fan to blow off the excess garlic skin after peeling, which provides convenience for the subsequent peeling work. The garlic stems and garlic heads are blown off the machine from one side by the built-in fan, and can be recovered; the divided garlic cloves roll out from the other side of the machine.

Garlic peeling machine

The garlic peeling machine adopts a specially designed peeling principle. During the peeling process, the garlic cloves are completely free of blade or hardness friction, ensuring the integrity, freshness and pollution-free of the processed product. The garlic cloves are not damaged and the peeling rate is high.

Garlic washing machine

The garlic cloves washing machine uses a bubble generating device to make the garlic granules in a tumbling state, effectively removing the transparent film residue on the surface of the garlic granules and cleaning the surface impurities. Floating matter can overflow from the overflow tank, and the sediment will be discharged from the sewage outlet to achieve the purpose of cleaning.

Garlic air drying system

Compared with the traditional drying and dewatering method, the garlic air drying machine has simple operation and high efficiency, can quickly remove the residual water droplets of the material, and has a high water removal rate (up to 95%).

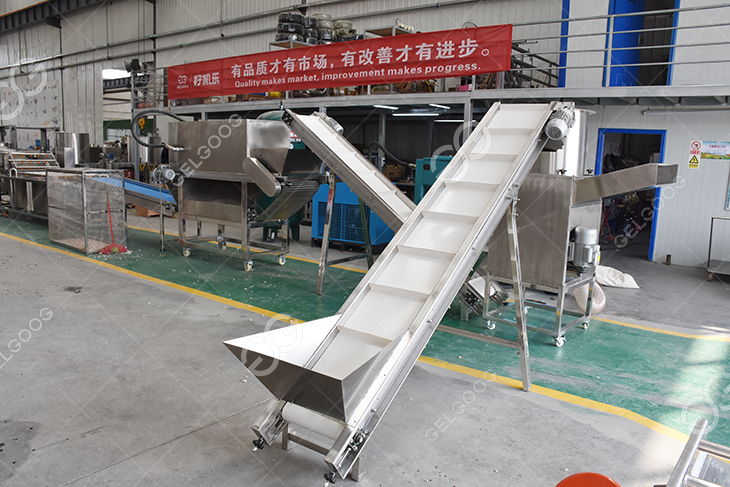

Here is our garlic bulbs pre-processing machinery working process in our factory youtube video for your reference!!!

Garlic paste grinding machine

After the garlic is ground and refined, the taste is smooth and delicate, which can well maintain its original various nutrients and has a good fresh-keeping effect.

Garlic paste emulsification mixing tank

The garlic sauce emulsification mixing tank mainly refers to the material in the vacuum state, using the kinetic energy brought by the machine, so that the garlic sauce can withstand hundreds of thousands of hydraulic shearing and centrifugal squeezing impacts in the narrow gap between the stator and the rotor per minute. The comprehensive effect of tearing, etc. instantly disperses and emulsifies uniformly, and after high-frequency cyclic reciprocation, a delicate and stable garlic paste without bubbles is obtained.

Garlic paste filling production line

Automatic garlic sauce filling production line process: manually put the bottle on the bottle feeding turntable-automatic bottle washing-automatic high temperature drying and sterilization-automatic filling-automatic capping and lowering-automatic vacuuming and screwing-automatic coding-automatic Labeling-manual bottle collection.

Except the garlic paste sauce making machine,we also have garlic flakes slicing machine, garlic flakes dehydrating machine, and garlic powder grinding machine.If you have any questions of the garlic processing, welcom to contact us freely!!

Reviews

There are no reviews yet.