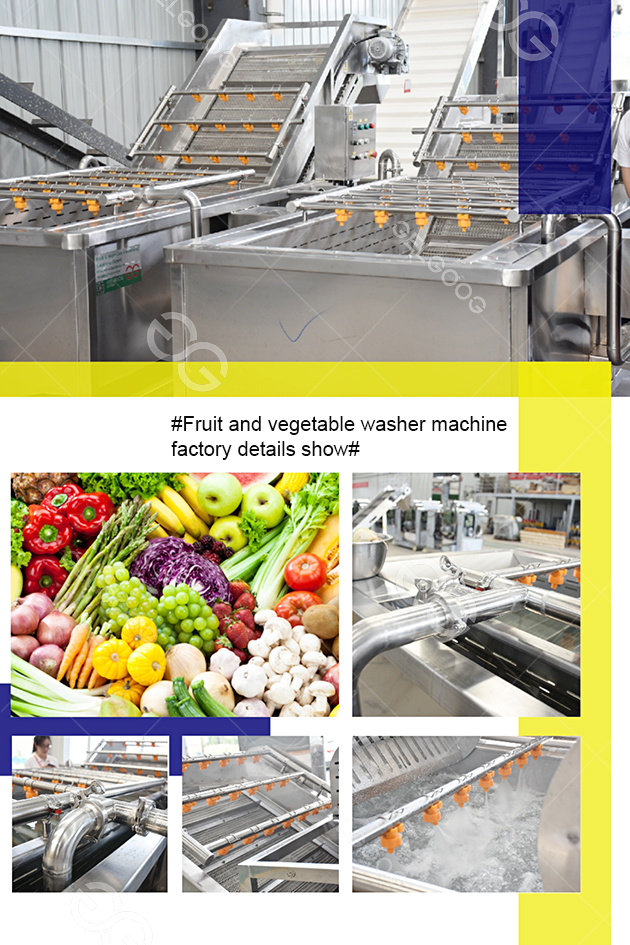

Description

Bubble washing machine vegetable and fruit is widely used and is selected by the majority of food washing process. Because the equipment replaces manual operation, it saves costs, solves labor shortage problems, improves production, improves product quality, and has advantages such as less investment.

Application

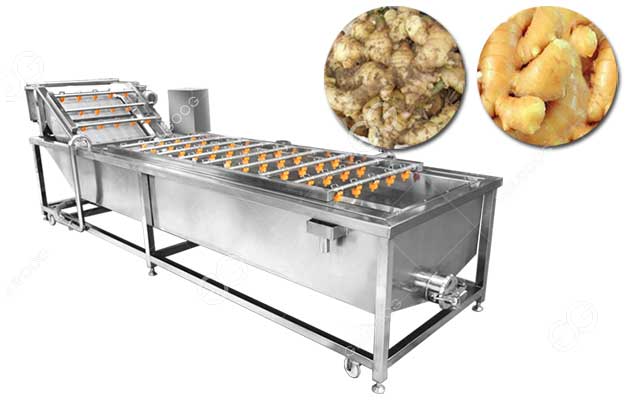

1. A variety of fruits and vegetables cleaning operations: peas, cauliflower, rape, cucumber, spinach,

2. A variety of agricultural products cleaning operations: wolfberry, jujube, chestnut, peanut, hawthorn, etc.,

3. A variety of seafood cleaning operations: fish, shrimp, starfish, crabs, etc.,

Parameter

| Model | Power kw | Size mm | Weight kg | Mesh width mm |

| GGXQ3000 | 2.2/0.75/1.5 | 3100*1400*1500 | 500 | 600 |

| GGXQ4000 | 4/1.1/1.5 | 4100*1400*1500 | 700 | 800 |

| GGXQ5000 | 5.5/1.5/2.2 | 5100*1400*1500 | 900 | 800 |

| GGXQ6000 | 5.5/1.5/2.2 | 6100*1400*1500 | 1000 | 800 |

| GGXQ7000 | 5.5/1.5/3 | 7100*1400*1500 | 1200 | 800 |

| GGXQ8000 | 5.5/1.5/3 | 8100*1400*1500 | 1350 | 800 |

| The above three powers are: air bubble, conveyor motor mesh belt and water pump. | ||||

Features

1. The bubble washing machine vegetable and fruit is equipped with a circulating water pump and a filter water tank to realize the recycling of cleaning water, save water, and replace with new water according to the actual situation;

2. The conveyor belt motor of the equipment can realize the function of adjusting the speed change. The cleaned vegetables are conveyed through the network chain, automatically fed and discharged, according to

Production needs to adjust the conveyor speed of the conveyor belt;

3. The equipment contains a spray device. After cleaning, it is transported to the next process, and the product is sprayed to reduce secondary pollution;

4. The plate part of the equipment is made of sus304 food grade stainless steel, which is not rusted or deformed, and it runs smoothly and is durable.

5. In the process of material conveying, the washing machine adds a spray cleaning function, so that after the material is cleaned in the steam bath, it can be cleaned by spraying.

Washing, the function of this process is to replace and remove the dirty water on the surface of the material to improve the cleaning effect of the material.

6. At the same time, the external cleaning spray water will automatically flow into the water bath after the material is cleaned twice, so as to replace the supplementary water bath.

The cleaning water inside maintains the cleanliness of the water in the water bath, which improves the utilization rate of the cleaning water and increases the cleaning effect.

Here is the leafy bubble washing machine working process for your reference!!

About the fruit and vegetable washing machine,we also have brush type washing machine for your reference!!

wendy –

Thanks for sharing