Description

The whole egg liquid pasteurization production line, also known as the egg liquid production line, is a special equipment for sterilizing egg liquid, generally at 58-60 degrees, which can sterilize whole egg liquid, and also can sterilize egg white and egg yolk. It has good sterilization effect and good sterilization. The shelf life can be extended.

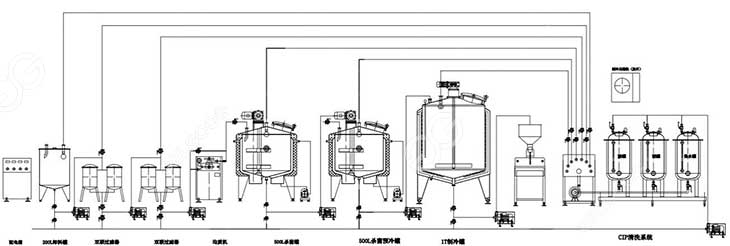

The whole egg liquid pasteurization production line is suitable for baking factories, egg processing plants, and many egg sellers. The sterilized egg liquid is distributed to the baking factory, using standard processing procedures, egg beating, egg washing, filtration, homogenization, sterilization, and refrigeration , Filling, cip cleaning, continuous work, high processing efficiency.

The above processing flow corresponds to the following equipment list:

| Number | Item | Parameter | Unit | Quantity |

| 1 | Unloading tank | 1、 200L, for feeding;

2、 Discharge port DN32, single layer, internal polishing; |

set | 1 |

| 2 | Sanitary centrifugal pump | 1. Flow rate: 3T, head 18 meters, four feet;

2. Motor power 1.5KW, alloy mechanical seal; 3. Material: 304 stainless steel; |

set | 6 |

| 3 | Cleaning the return pump | 1. Flow rate: 10T, head 30 meters, four feet;

2. Motor power 3.0KW, alloy mechanical seal; 3. Material: 304 stainless steel; 4. For cyclic cleaning; |

set | 1 |

| 4 | Duplex filter | 1. Material: 304, 2 sets of filters; | set | 2 |

| 5 | Homogenizer | 1. The highest pressure is 25MPA; output: 500L/hour;

2. Power: 4KW; |

set | 1 |

| 6 | 500L pasteurization tank | 1、 1. Specifications: 500L, three-layer vertical, heating at the bottom, with tap water for cooling;

2、 2. Heating power: 24KW, with additional water pump circulation; 3、 3. Stirring device: power 0.75KW, 60r/min; wall scraping and stirring 4、 4. Material: 304 stainless steel; thickness of steel plate: thickness of inner tank 2.5mm; inner polishing; 5、 5. Import and export diameter: Φ38/38 for fast loading, the discharge port is 350mm high from the ground; 6、 Equipment configuration: quick opening manhole, CIP cleaning ball, temperature display; |

set | 2 |

| 7 | 1T vertical refrigeration tank | 1. Specifications: 1000L, three-layer vertical, Miller board refrigeration;

2. Stirring device: power 0.75KW, 60r/min; 3. Material: 304 stainless steel; liner thickness 2.5mm; internal polishing; 4. Import and export diameter: Φ38/38 fast loading, the discharge port is 350mm from the ground; 5. Equipment configuration: quick opening manhole, CIP cleaning ball, temperature display; 6. Equipped with imported 3P compressor (the customer is responsible for the installation of the outdoor compressor); |

set | 1 |

| 8 | Piston filling machine | 1. Single-head semi-automatic piston filling machine;

2. Suitable for fluid filling, accurate quantification; 3. Customized 5kg filling, can filling in various forms of bags, bottles and barrels; 4. Customers provide their own air compressors; |

set | 1 |

| 9 | CIP cleaning system | 1. 300L, acid and alkali tank, automatic constant temperature;

2. Vertical double-layer insulation; 3. Heating power: 36KW, equipped with a 5T cleaning pump; |

set | 1 |

The whole egg liquid pasteurization production line is divided into two types, tank type and plate type. Whether it is one ton a day or three tons an hour, we can customize it. Whether it is a sterilization refrigeration tank, pipeline, valve, and centrifugal pump, 304 are used. Stainless steel material, the equipment is very durable.

The whole egg liquid pasteurization production line adopts low-temperature sterilization. Generally, it is sterilized at 60 degrees for 30 minutes to an hour. The quality of the sterilized egg liquid is good. The whole production line has many equipments. The pipeline needs to be disassembled for delivery. We will install and debug in the past.

Reviews

There are no reviews yet.