Nowadays, the crises of pesticide residues frequently appear in the news, and everyone is beginning to worry about whether the daily use of fruits and vegetables will be harmful. The pesticide residue incident has attracted the attention of many families for a while.

In order to ensure that the fruits and vegetables we eat every day are healthier, the fruit and vegetable washer machine has appeared, but is the fruit and vegetable machine really work? Many people have searched for various fruit and vegetable washing machines on the Internet, and they also asked questions on Google. Does fruit and vegetable washer machine really work?” This kind of question.

However, I believe that most people still don’t know whether the fruit and vegetable washer machine is useful, and there are still various doubts and doubts about the efficacy of the fruit and vegetable washing machine. To know whether the household fruit and vegetable cleaning machine is useful, you must first understand the principle of the fruit and vegetable cleaning machine. What is the working principle of the fruit and vegetable cleaning machine?

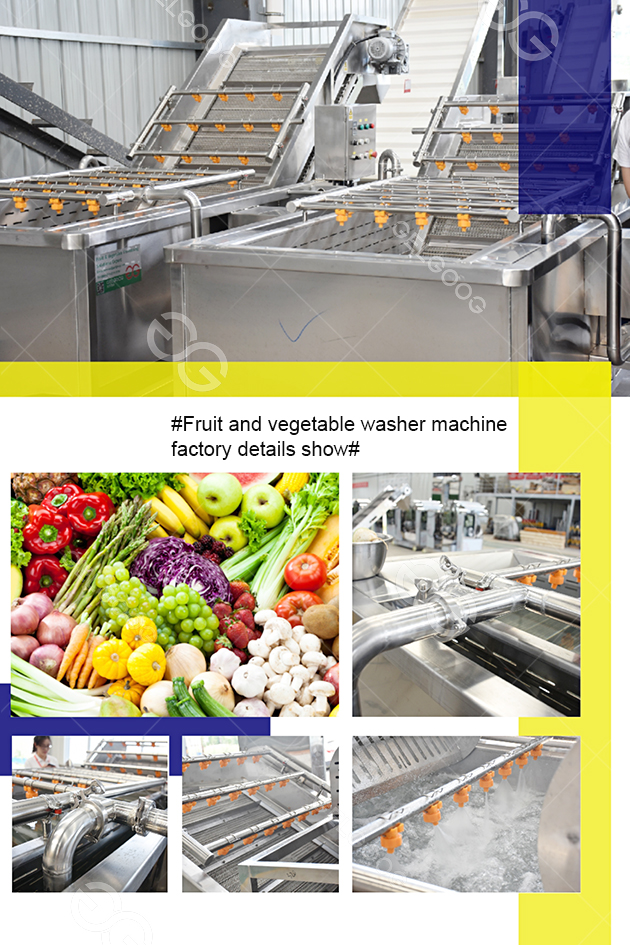

The fruit and vegetable washer machine adopts bubble water bath to clean the fruit and vegetable food using bubble surfing and water circulation to clean and remove the sediment and other attachments on the product. Under the combined work of bubbles, surfing, lifting, spraying, etc., the equipment has the characteristics of high cleaning, energy saving and water saving, and stable and reliable equipment. It is suitable for the cleaning of various fruits, vegetables (fresh vegetables, pickled vegetables, fungus vegetables), aquatic products, and medicinal materials. It can be customized according to the output size. The equipment is made of high-quality stainless steel and meets food hygiene standards.

When the material enters the machine body, the air pump device is turned on. Under the action of high-pressure water flow and strong air bubbles, the air bubbles are used to strongly impact the surface of the object, and the materials are fully dispersed, rolled, cleaned and transported. After the heavy dirt such as mud and sand on the material is separated, it falls into the sedimentation area under the mesh belt, and no upturning and backflow will cause re-pollution.

Through the water circulation of the circulating water pump, the impurities enter the filter box to remove most of the impurities and improve the cleaning effect; other floating objects flow out of the main tank through the overflow system, and the materials are gradually moved to the conveyor belt under the push of water and lifted out The inner tank body is sprayed and cleaned to clean the materials for the second time and enter the following process. During the lifting process, the product is sprayed again through the clean water spray pipe to further clean the product. While ensuring the cleanliness of the product, it can also replenish the water source in the equipment tank in time to ensure the cleanliness of the water source in the equipment and achieve the cleaning effect. After the cleaning is completed, the inner tank is lifted out and enters the next process. In the working process, the medium water is filtered through the filter water tank to remove impurities, and then the filtered water is pumped into the main tank through the circulating water pump to realize the recycling and reuse of the water, which saves energy and is environmentally friendly and hygienic; upgrade part of the upper spray pipe Always supply water so that the sewage in the water tank is gradually replaced.