Tomatoes are a versatile and widely consumed vegetable with a myriad of culinary applications. To meet the growing demand for processed tomato products, establishing a tomato processing plant can be a lucrative venture. But what is the cost of small scale tomato processing plant? This article delves into the various aspects and costs involved in setting up such a plant.

Market analysis:

Before diving into the cost details, it is crucial to conduct a thorough market analysis. Identify the demand for tomato-based products in your target region. This will guide your production volume and product range, ensuring your plant aligns with market needs.

Location and infrastructure:

The location of your plant plays a significant role in the overall cost. Consider proximity to raw materials, transportation facilities, and labor availability. Infrastructure costs include land, building construction, utilities, and other amenities. Be sure to comply with local regulations and zoning requirements.

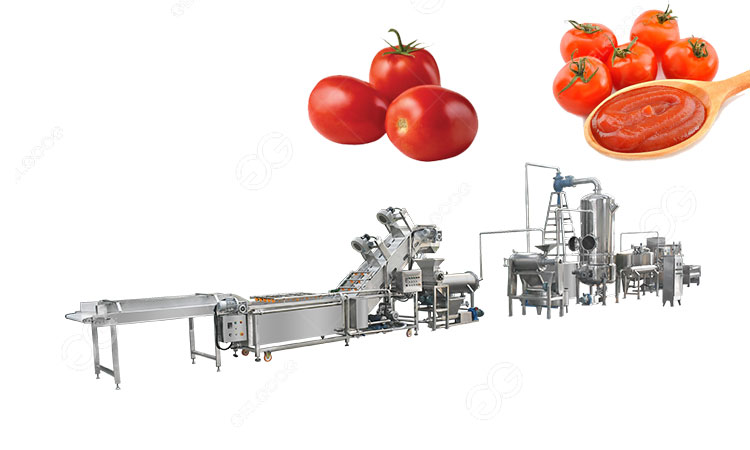

Tomato processing equipment costs:

The heart of any processing plant lies in its machinery. For a small-scale tomato processing plant, essential equipment includes washing machines, sorting conveyors, pulping machines, evaporators, sterilizers, filling and packaging machines, and storage facilities. The cost of this equipment varies based on capacity and brand reputation. It is advisable to invest in reliable, energy-efficient machinery to ensure long-term sustainability.

Labor costs:

Labor is a significant component of operational expenses. Consider the number of skilled and unskilled workers required for various processes, such as sorting, washing, pulping, packaging, and quality control. Additionally, factor in training costs to ensure the efficiency of your workforce.

Raw material procurement:

The primary raw material for tomato processing is, of course, tomatoes. Establish relationships with local farmers or distributors to ensure a steady and cost-effective supply. Factor in transportation costs for bringing the raw materials to your processing plant.

Utilities:

Consider the costs associated with water, electricity, and fuel consumption. Tomato processing involves water-intensive processes like washing, and machinery requires energy to operate. Invest in energy-efficient technologies and explore sustainable practices to reduce utility expenses.

Quality control and safety measures:

Implementing quality control measures is crucial to ensure the consistency and safety of your products. Budget for laboratory equipment, testing protocols, and safety measures to comply with food safety standards.

Packaging and distribution:

Packaging is an essential aspect of marketing your products. Include the costs of packaging materials, labeling, and distribution logistics in your budget. Sustainable and attractive packaging can contribute to the overall success of your product in the market.

Regulatory compliance:

Understand and budget for regulatory requirements, including licenses, permits, and inspections. Compliance with food safety standards is non-negotiable and can affect the success and reputation of your processing plant.

Contingency and working capital:

Set aside a portion of your budget for unforeseen circumstances and working capital. This ensures you have the financial flexibility to navigate challenges and maintain smooth operations.

Establishing a small-scale tomato processing plant involves careful planning and financial consideration. By thoroughly assessing the market, understanding the costs involved, and prioritizing efficiency and quality, entrepreneurs can embark on a rewarding journey in the tomato processing industry. With a well-executed business plan, attention to detail, and commitment to quality, a small-scale tomato processing plant can become a sustainable and profitable venture.