Description

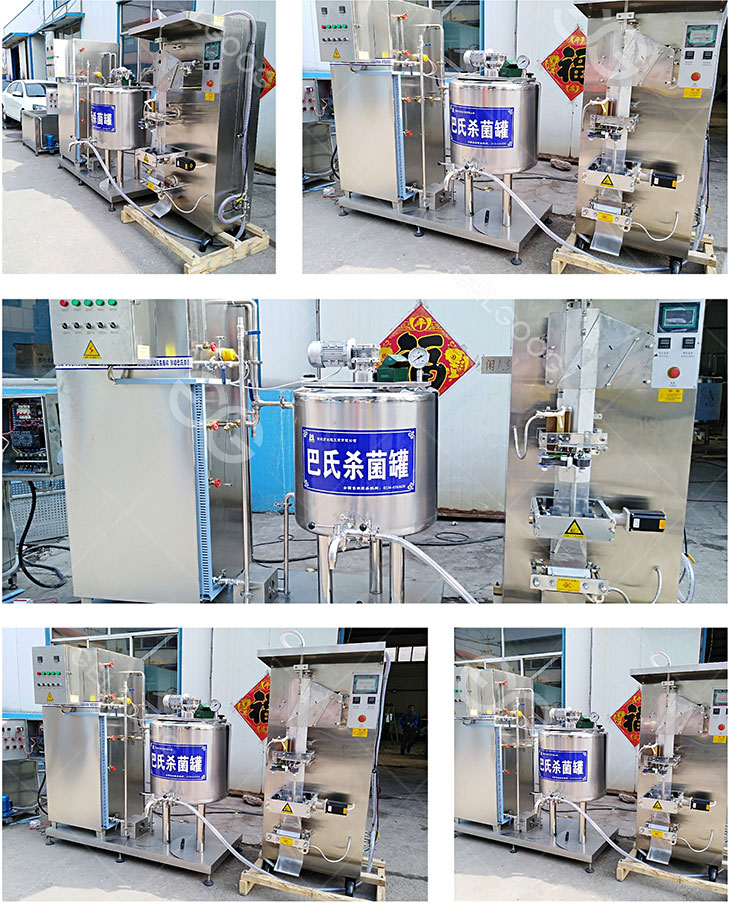

Our small scale milk pasteurization equipment with 304 stainless steel material,it can process the fresh milk to pasteurized milk.

The characteristic is that it is sterilized at a constant temperature of 72℃-85℃ within a specified time, which can kill harmful bacteria in the milk while being intact.

The nutrients and pure taste are preserved.The active ingredients in the fresh milk are preserved, and the milk is nutritious, fresh and original.

How Milk Pasteurizer Works?

The principle of bacteria is that within a certain temperature range, the lower the temperature, the slower the bacteria multiply; the higher the temperature, the faster the multiplication. But if the temperature is too high, the bacteria will die. Different bacteria have different suitable growth temperature, heat and cold tolerance.

Pasteurization is actually the use of pathogens that are not very heat-resistant, and treatment with appropriate temperature and holding time to kill them all. However, after pasteurization, a small part of harmless or beneficial, more heat-resistant bacteria or bacterial spores remained.

Commercial Milk Pasteurizer Application:

The small scale milk pasteurization equipment is widely used to determine and update the original formula of fresh milk, yogurt, goat milk, camel milk, fruit juice, milk-containing beverages and condiments, etc.

Small Pasteurization Machine parameters

| Name | Model | Power(KW) | Dimension(MM) | Weight(KG) | sterilizing time | sterilizing temprature |

| Pasteurizing Machine |

GGJP50 | 4.5 | 650x650x1000 | 55 | 15seconds(adjustable) | 65-95℃(adjustable) |

| GGJP70 | 6.5 | 750x750x1200 | 70 | |||

| GGJP100 | 6.5/9.5(380V) | 850x850x1350 | 85 | |||

| GGJP150 | 6.5/9.5(380V) | 950x950x1500 | 100 | |||

| GGJP300 | 20(380V) | 1100x1200x1800 | 185 |

Small Milk Pasteurizer Features

1. The small scale milk pasteurization equipment operation adopts frequency conversion stepless speed regulation, and the operation is stable; the main body of the equipment is made of stainless steel.

2. The sterilization time of the sterilization equipment is adjustable from 10 to 30 minutes; the sterilization temperature is instantly adjustable from 60 to 99 and is equipped with an automatic temperature control device.

3. The sterilization tank is equipped with heat preservation facilities and temperature compensation device, which effectively guarantees the balance of water temperature in the tank and ensures the sterilization effect.

4. The pasteurizer realizes the modern design concept, its automation degree is high, and the equipment design is reasonable and reasonable.

5. Sterilization temperature range 65°C—95°C can be adjusted by itself, and the temperature control can reach ±1°C.

6. The machine is equipped with a 360-degree rotating cleaning nozzle and a cleaning centrifugal pump. The whole machine can achieve automatic cleaning of the equipment.

The dairy farm commercial milk pasteurizer can completely simulate the production status of an industrial pasteurizer, integrating heating, sterilization, emulsification, and cooling. This equipment can be equipped with a small aseptic filling machine, glass bottle and composite bag filling machine as needed.

It is the ideal equipment for universities, milk bars, small pasteurized milk manufacturers. It can be used in combination with multiple cans as needed, which is very suitable for small batches and multiple varieties of fresh milk bars and small and medium-sized dairy farms.

Reviews

There are no reviews yet.