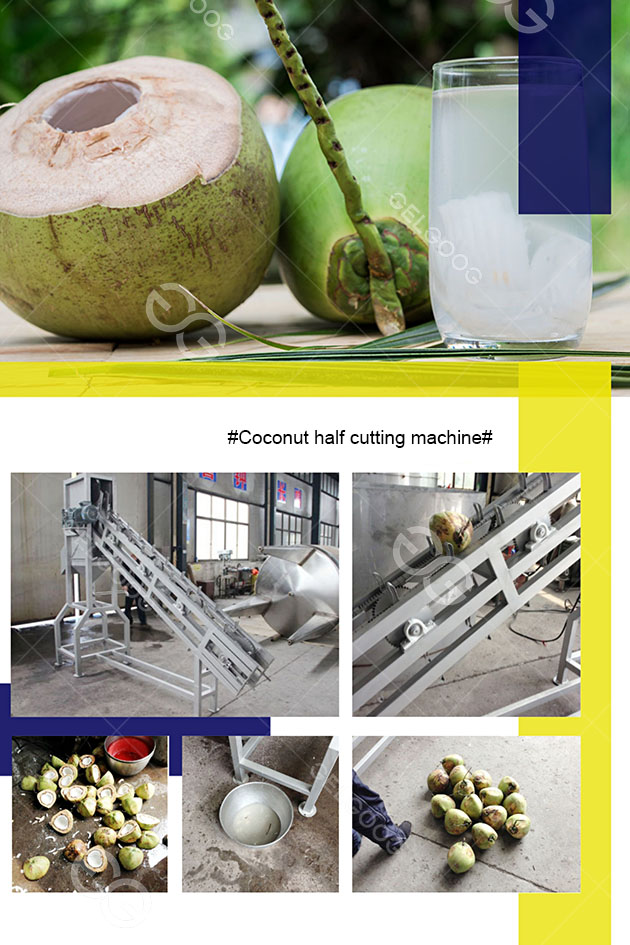

Description

This tender coconut half cutting machine is suitable for halving coconuts for coocnut water. The machine is designed with compact structure, low noise and convenient use. The whole material is stainless steel.

For the removal of coconuts after maturity, the market generally uses manual or mechanical rollers to remove the thick fiber outside, then use a sharp chisel to punch holes in the brown stone of the awl, and put it in the straw to get the coconut water.

This kind of coconut operation method is not only inefficient and prolonged in labor consumption, but at the same time, the utilization value of coconut is greatly reduced.

The coconut cut half cutting machine is used as the pre-equipment in the coconut production line to provide a mechanized operation with high extraction rate and stable operation for the extraction of coconut milk and coconut meat. At the same time, the coconut shell cut in half can also be run to the next process for coconut meat extraction.

Coconut Half Cutting Machine Structure

The Coconut Half Cutting Machine is mainly include of important parts such as frame, conveying chain, juice hopper, slag hopper, shift frame, transmission reducer and so on.

Parameter:

Production capacity: 800-1000 pcs/h

Equipped with power: 2.2kw

Conveying speed: 22m/min

Dimensions: 3300×820×2500mm

Tender Coconut Opener Working Principle

After manually placing the coconut on the baffle of the conveyor chain, it is driven by the driving shaft to move upward, and the shift frame rotates along with it.

Under the interaction of the various transmission parts, the conveyor chain continues to rotate.And slowly lift the coconut to the bottom of the rack.

The top of the machine has a fixed blade, so that the coconut is cut in half under the action of the mutual force of the blade and the rack.

The half-cut juice flows into the juice hopper. We install a row of bars above the juice hopper to prevent the coconut shell from falling into the juice hopper. The bars are at a certain angle, and the coconut shell is introduced to the slag hopper from the bar.

Tender coconut Half Cutting Machine Installation

- You need to install it firm and in the level rack.

- Before starting the machine, check whether the screws in each part are tight.

- Before using this machine,you should add once grease to each bearing and stepless transmission,and the once every six months;

- Turn on the power, start the stepless transmission, check whether the conveyor chain is tightened, if it is loose, adjust the tensioning screw to tighten the conveyor belt.

- You need strictly forbiden stons,screw,and tools from falling into the equipment,so you can prevent them falling into the next process.

- Test run several times, each time no more than 20 minutes, cut off the power supply, re-check according to the above requirements, and only after confirming that it is correct, can the feed test run.

- Lubricate all parts of the machine regularly.

- After shutdown, you should to clean the inside and outside of the whole machine to keep it clean.

Here is the coconut cutting machine working process for your reference!!

If you want to do the tendar coconut business,only this tender coconut half cutting machine is not enough,bufore cutting you need to washing them.And after cutting the tendar coconut,you need a tank to stroe the coconut water temporary.

Then you need the duplex filter to filtering the fine impurities in the coconut water,after filtering you also need to sterilization, filling process.

We are professionals in coconut processing for 10 years,any questions of the coconut processing, you can feel free to ocntact us online!

Reviews

There are no reviews yet.