Description

Chili paste production line is an automated production equipment designed for producing all kinds of chili paste. With this production line, you can produce high quality chili paste products quickly and efficiently to meet the market demand. You can also use this chili paste production line to produce tomato hot sauce.

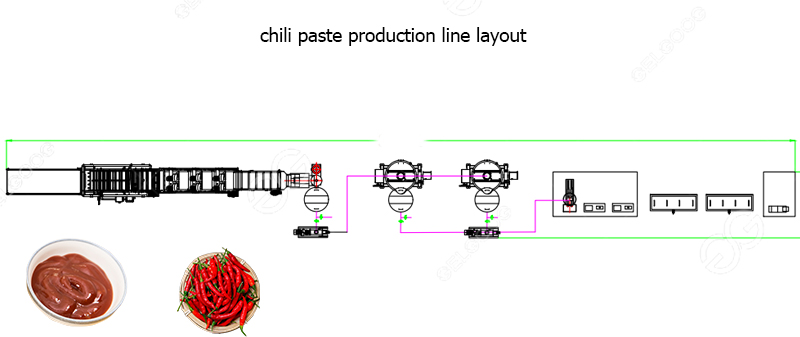

Chili Paste Production Process:

washing→ remove water→crushing→grinding→cooking→filling→sealing→sterilizing

Washing: Under the action of bubbles and spray, impurities, dirt and pesticide residues on the surface of chili are removed.

Remove water: After cleaning the chili you need to remove the excess water. This helps to improve the consistency of the chili paste and enhances the taste and texture.

Crushing: The cleaned chili are crushed into fine particles. This step ensures that the chili are uniform and easy to process.

Grinding: This is a critical step in transforming the chili into a chili sauce. The chili particles are thoroughly ground into a fine paste, releasing the aroma and flavor of the chili.

Cooking: Seasonings such as salt, sugar and vinegar are added to the chili paste according to the recipe, and then cooked at a certain temperature so that the various seasonings are fully integrated.

Filling: After cooking, the chili paste is conveyed to the filling machine, which automatically fills it into pre-prepared containers.

Sealing: Once the filling is complete, it is sealed to maintain its freshness and quality while preventing the entry of outside air and microorganisms.

Sterilizing: Sterilize the sealed chili paste to ensure the safety and long-term preservation of the product.

Chili Paste Production Line Features:

- Automated production: the pepper paste production line realizes fully automated production from chili pepper treatment to filling, which saves labor cost and improves production efficiency.

- Precise control: The pepper paste production line is equipped with advanced control system, which can accurately control the temperature, time and other parameters of each link to ensure the stability of the quality of chili pepper paste.

- Flexibility: The production parameters can be adjusted according to the requirements of different formulas, to produce a variety of flavors of chili pepper paste products to meet the different needs of the market, such as pepper paste, tomato hot sauce, etc.

- Hygiene and safety: made of high quality stainless steel material, easy to clean, no pollution, in line with food hygiene standards.

Technical Parameters:

Production capacity: According to different specifications of the pepper paste production line, the production capacity can reach 300-1000kg per hour.

Equipment size: The size of the line can be customized according to the customer’s needs, adapting to different plant space, to ensure the rationalization of the layout of the factory.

Reviews

There are no reviews yet.