Description

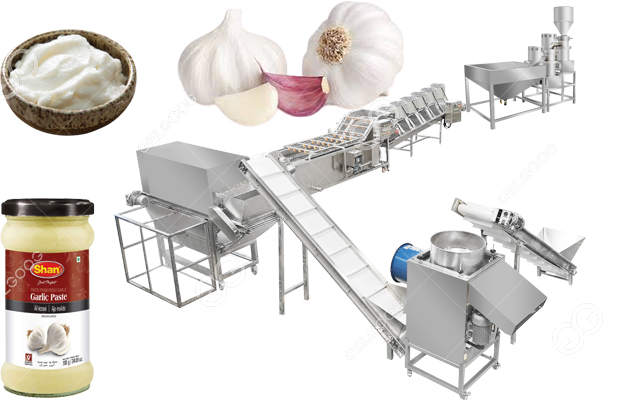

Garlic paste processing plant are becoming more and more popular with local garlic processing investors in Middle Eastern countries where garlic is mainly imported, especially in Algeria, Saudi Arabia, UAE and other countries. The garlic sauce production line can help customers in Algeria to break, peel, clean, grind, sterilize, and pack imported garlic, thereby extending the shelf life of garlic. And there are many ways to eat garlic sauce in the Middle East. It is very common with bread, pizza, potato chips, burgers and fried chicken.

Algeria’s garlic sauce production line mainly includes garlic clove breaking, garlic peeling, garlic washing, garlic grinding, garlic paste sterilization, garlic paste packaging, and the link between equipment through lifting devices and pumps.

Garlic clove breaking machine:

The garlic clove breaking machine is to peel garlic into garlic cloves, use a soft roller to simulate hand peeling, so that the garlic ball can achieve the peeling effect, and adopts an exclusively developed adjustable method. The operation is simple. The size of the garlic ball can be used. The garlic cloves are not easy to damage, and the peeling rate is high. Small size, high efficiency, one person can operate. The garlic clove breaking machine uses a built-in fan to blow off the excess garlic skin after peeling, which provides convenience for the subsequent peeling work.

Garlic peeling machine:

The garlic peeling machine processes the broken garlic into garlic cloves without any damage. The garlic cloves can be peeled using this machine without soaking in water. Suitable for any variety of garlic such as white garlic and black garlic. It is made of carbon steel and stainless steel (except for transmission parts). With air compressor as the production power, the garlic can be guided, peeled and discharged automatically through electric and pneumatic control.

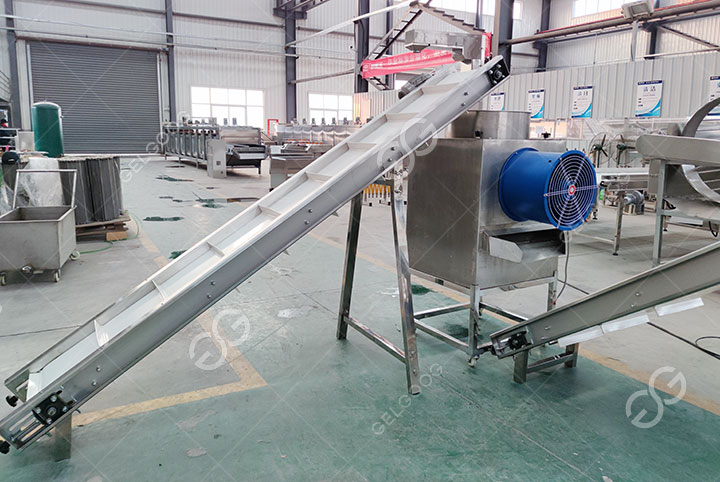

Garlic washing and drying machine:

The peeled garlic is dropped into the water through the hoist, and the garlic is stirred and cleaned with the churning water in the tank. After the white film and other dirt on the garlic are removed, it falls into the sedimentation area under the filter. Pushed by the water, it gradually moves to the conveyor mesh belt and is lifted out of the inner tank. After spray cleaning, the material is washed for the second time and enters the following process.

The surface of the washed garlic usually has residual water droplets. In order not to affect the subsequent operation, it is necessary to quickly dry the excess water droplets on the garlic surface through a garlic air dryer.

Garlic paste grinding machine:

The garlic paste grinding machine also called colloid mill can grind the cleaned and air-dried garlic into garlic paste. When the garlic is ground into garlic paste under the high-speed rotating friction between the customized rotors, the temperature of the garlic paste will increase. In order to facilitate the packaging of the garlic paste as soon as possible, Use jacket cooling to reduce the temperature of the garlic sauce.

Garlic paste packaging machine:

There are many packaging forms of garlic sauce, bagged, bottled, etc. We can configure different garlic sauce packaging machines for you according to your packaging form. Generally, we use a paste filling machine for garlic packaging, which is compatible with 5 types of bottles and does not require replacement of accessories; 2 metering methods can be used for quantitative and fixed liquid level; high efficiency, increasing 70% canning efficiency.

Garlic Paste Processing Plant Advantages

1. It can alleviate the scarcity of garlic in Algeria in the Middle East and the storage problem of imported garlic;

2. Use food-grade stainless steel to ensure the safety and sanitation during garlic processing;

3. Support customized services, and provide customized garlic processing solutions according to customer needs;

Reviews

There are no reviews yet.