Description

We are a apple juice production line manufacturers. Apple juice is mainly divided into apple clear juice and apple juice. We support the apple juice processing lines suitable for the production of clear apple juice.

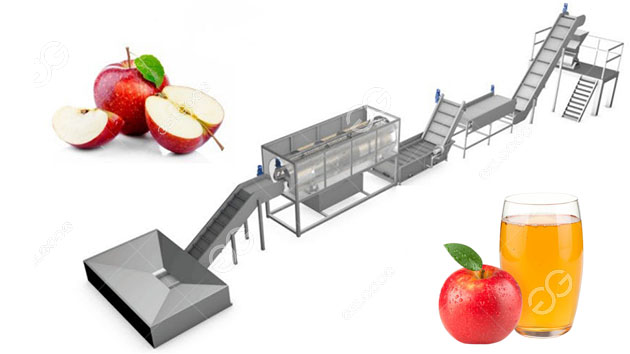

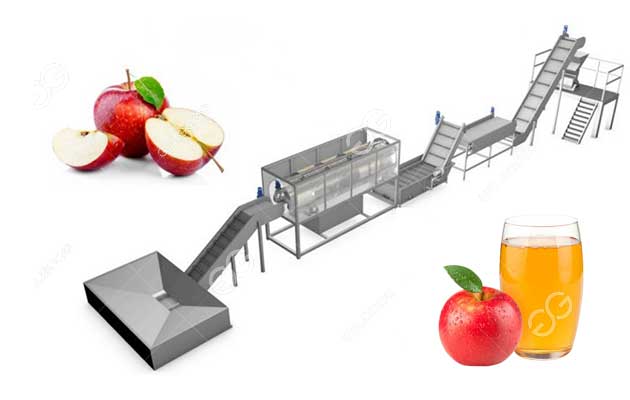

Process flow of apple juice processing line:

Fresh apples→washing→picking→lifting→crushing and juice extraction→enzyme inactivation→filtering→blending→homogenization→degassing→sterilization→filling→secondary sterilization→coding→labeling. The above processes have specific equipment:

1. Apple Cleaning: Two cleaning processes. First, use a bubble cleaning machine to clean the surface of apples, and then perform flat roller cleaning for further cleaning of apples. Add a soft brush inside and spray rinse outside to make the cleaning more thorough.

pick apple

pick apple

2. Picking belt: Manually pick the cleaned apples to pick out bad fruits, rotten fruits and apples with bug eyes.

3. Lifting: A 3-meter stainless steel lifter transports the apples to the feeding port of the crushing juicer.

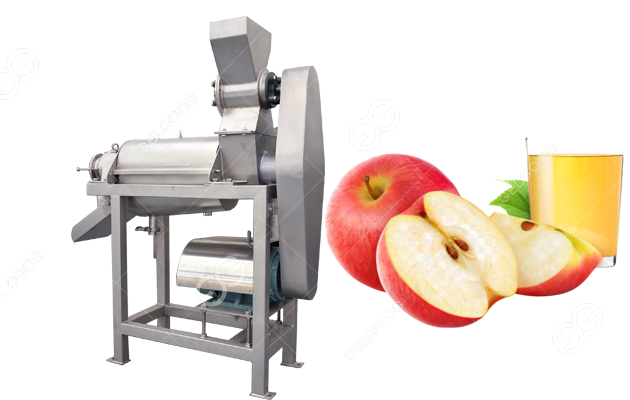

4. Juice ectractor with crush: A juicer with a crushing function, which can crush the apple first, and then squeeze the juice.

5. After the buffer tank, juice pump, enzyme killer, filter, blending tank, homogenizer, deaerator, and sterilizer, the finished apple juice is finally obtained. It should be noted that the filter is a very important process. Can filter the meat in the apple juice, and finally get the apple juice.

6. 3-in-1 filling machine: filling the clear apple juice, screwing and packaging.

7. Spray sterilization cooler: the bottled apple juice is sterilized twice at high temperature.

8. Finally, through the drying machine, inkjet printer, sleeve labeling machine, we get the apple juice drink that we often see in supermarkets.

Advantages of apple juice production line:

1. Two sterilization processes, pre-sterilization and post-sterilization can ensure the cleanliness of the entire apple juice production process.

2. Two cleaning processes, bubble cleaning and flat roller cleaning can clean the apple more thoroughly.

3. Increasing the enzyme inactivation process can inactivate the polyphenol oxidase (PPO) and pectin methyl esterase (PME) in the apple juice, reduce the browning phenomenon in the subsequent production process and slow down the process of fermentation deterioration.

4. Filtration process, we use a double filter to filter the screen with a mesh number of up to 400 meshes and a filtration area of 0.25 square meters, which can completely separate large particles of apple meat and other impurities.

As a apple juice production line manufacturers for 10 years,our juice processing line include the following features:

The layout and routing are designed according to the size and characteristics of the plant to ensure the rationality of the construction and operation of the apple juice production site, and a good on-site working environment;

The equipment layout of the apple juice production workshop is compact and the space is wide, achieving the economic and aesthetic design effect of a modern production workshop;

Each production link of apple juice considers energy-saving design and heat recycling, which greatly reduces energy consumption and saves more than 20% of energy compared with equipment in the same industry;

The unique design process and pipeline connection arrangement can retain the original natural aroma components of the apple and ensure the original taste of apple juice.

Reviews

There are no reviews yet.