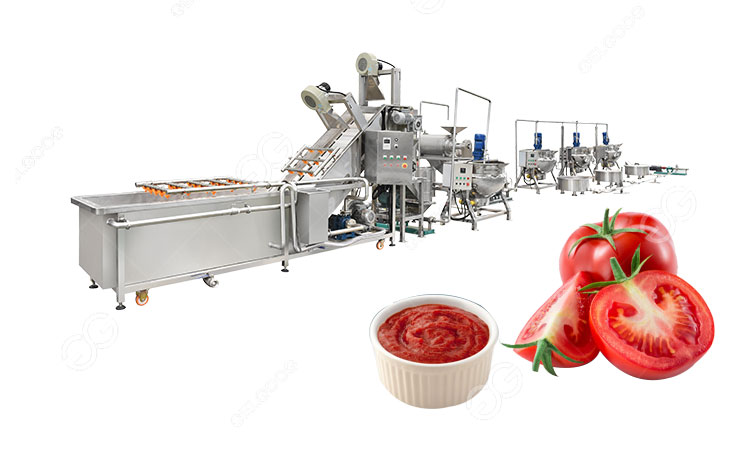

The production of tomato sauce in a factory involves a series of carefully orchestrated steps, each facilitated by specific equipment designed to ensure efficiency and quality. From initial preparation to the final packaging, a variety of machines play integral roles in the process. But what equipment is used to make tomato sauce?

To kickstart the tomato sauce production line, washing machines are employed to thoroughly clean and sanitize the tomatoes. This crucial step ensures that the raw material is free from impurities, dirt, and contaminants. Clean tomatoes set the foundation for a high-quality end product.

Following the washing stage, the tomatoes move on to the crushing machine. This equipment is designed to break down the tomatoes into a pulpy consistency, separating the skin and seeds from the desirable pulp. The crushed tomatoes are then transferred to a pulping machine, which further refines the mixture, extracting a smooth and uniform pulp. This is a key step in achieving the desired texture and consistency of the tomato sauce.

Sterilization is a critical phase in the production of any sauce to ensure the final product is safe for consumption and has an extended shelf life. Sterilizers, often utilizing heat or other sterilization methods, eliminate harmful microorganisms and enzymes. This step contributes significantly to the preservation of the sauce.

The next stage involves the filling machine, a piece of equipment designed to precisely measure and dispense the tomato sauce into containers. These machines are equipped with mechanisms to ensure accurate filling, reducing wastage and maintaining consistency across batches. The choice of container, whether glass jars, cans, or pouches, often determines the type of filling machine used.

Once filled, the containers move to the sealing and packaging phase. Sealing machines secure the containers, ensuring product integrity and preventing contamination. Packaging machines then handle the final stage, preparing the tomato sauce for distribution. These machines may involve labeling, coding, and boxing the finished products, ready for shipment to retailers or consumers.

Throughout the entire process, quality control measures are implemented to monitor factors such as color, taste, and viscosity. Additionally, automation plays a crucial role in enhancing production efficiency, reducing manual labor, and minimizing the risk of human error.

In conclusion, the production of tomato sauce in a factory relies on a range of specialized equipment, from washing and crushing machines to sterilizers, filling machines, and packaging equipment. Each stage contributes to the creation of a high-quality, consistent product that meets both industry standards and consumer expectations.