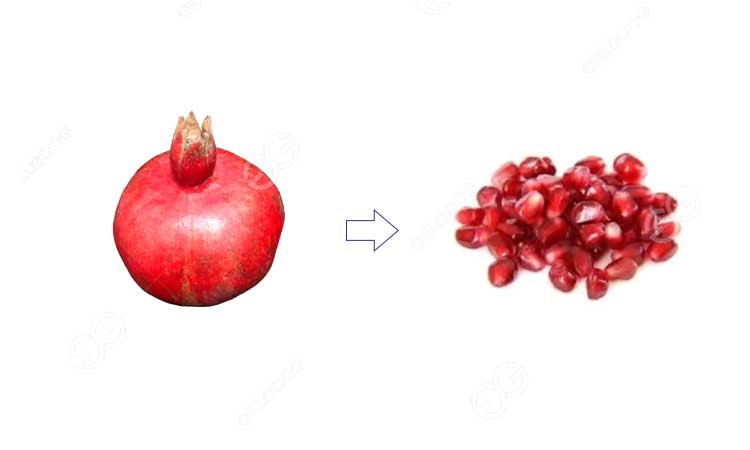

Pomegranates, with their jewel-like seeds encased in a tough, leathery skin, have been cherished for their vibrant flavor and potential health benefits for centuries. The process of deseeding pomegranates, however, can be a tedious and time-consuming task. Fortunately, modern technology has come to the rescue of commercial pomegranate processing with the advent of automatic pomegranate peeling machines. In this article, we will explore how are pomegranates deseeded in a factory.

The traditional challenge of deseeding pomegranates

Before the introduction of automatic peeling machines, deseeding pomegranates was a labor-intensive and slow process. Typically, it involved manual labor, where workers would cut off the crown of the pomegranate, score the skin, and painstakingly remove the seeds by hand. This method not only required a significant workforce but also resulted in a slower processing rate and often led to substantial product wastage due to damage to the seeds during manual extraction.

Automatic pomegranate peeling machines

Automatic pomegranate peeling machines have transformed the pomegranate processing industry by significantly increasing efficiency, reducing labor costs, and minimizing seed damage. Here’s how these machines work:

- Feeding and sorting: The first step in the automated process is feeding the pomegranates into the machine. The fruits are loaded onto a conveyor belt and are sorted for size and quality to ensure consistent output.

- Cutting and scoring: As the pomegranates move through the machine, they are cut and scored. The cutting mechanism usually employs a series of blades or knives that precisely cut the top crown and score the skin without damaging the seeds inside.

- De-seeding: Once scored, the pomegranates are gently broken apart, and the seeds are separated from the inner membranes. This step is crucial as it ensures that the seeds are separated without being crushed or damaged.

- Seed collection: The separated seeds fall through a series of screens and chutes that remove any remaining bits of membrane, leaving behind clean, intact pomegranate seeds. These seeds are then collected for packaging or further processing.

Benefits of automatic pomegranate peeling machines

- Increased efficiency: These machines can process pomegranates at a much faster rate compared to manual deseeding, increasing overall production efficiency and output.

- Labor reduction: Factories can significantly reduce their labor costs as fewer workers are required to operate the machines. This also eliminates the need for hiring and training manual laborers for this repetitive task.

- Consistency and quality: Automatic machines ensure a consistent level of quality and precision in the deseeding process, resulting in a higher-quality product with minimal seed damage.

- Reduced waste: Manual deseeding often leads to wastage due to seed damage. Automatic machines minimize wastage, making the process more cost-effective and environmentally friendly.

- Hygiene and safety: Automation reduces the risk of contamination and injury associated with manual processing, enhancing the overall safety and hygiene of the production environment.

The machine has revolutionized the way pomegranates are deseeded in factories. They offer numerous advantages, including increased efficiency, reduced labor costs, improved product quality, and reduced waste. As the demand for pomegranate products continues to grow, these machines play a crucial role in meeting that demand while maintaining high standards of quality and consistency in the industry.

If you are interest in the machine, contact us now sherry@machinehall.com