Description

The sweet corn processing plant can process the harvest fresh green leafy sweet corn from farm into vacuum packed sweet corn or canned corn kernels.

The sweet corn processing plant mainly include corn peeling – corn grading – corn picking – corn cleaning – (corn threshing) corn blanching – corn cooling – air drying – vacuum packaging – high temperature sterilization – draining – air drying and packing.

In the processing of corn, the cleaning of corn is a very important link. Corn cleaning is to clean the corn silk and insect egg impurities on the corn surface. Whether the corn is cleaned or not affects the processing quality of the corn.

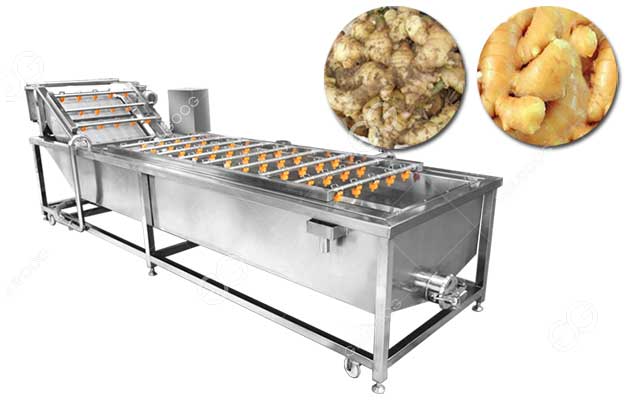

Sweet Air Bubble Washing Machine

After peeling the sweet corn green leafy ,we use air bubble to washing the sweet corn firstly.The high-pressure water flow makes the corn in a tumbling state, removing pesticide residues on the surface of the product. Floating matter in the vegetable washing machine can overflow from the overflow tank, and the sediment is discharged from the mouth to achieve the purpose of cleaning.

Tips:Before we washing the sweet corn ,we need to peeling the sweet corn green leafy,then to washing and blanching them.

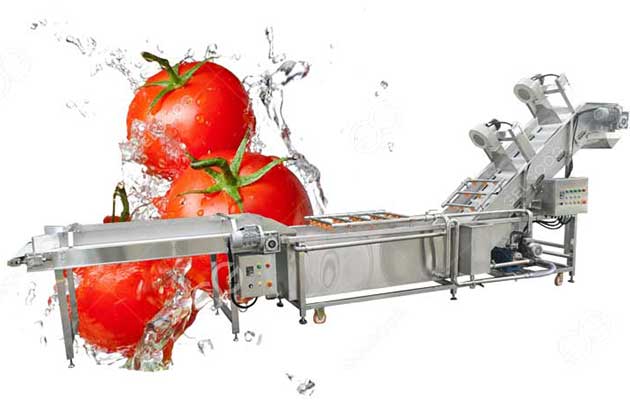

Sweet corn washing machine

For corn second cleaning, we use bubble spray cleaning. The equipment is equipped with multiple high-pressure water pumps to spray out water under pressure. The conveying of corn adopts a roller type conveying method. The gap between the rollers is set according to the actual corn ear size.

The rotation of the roller is used to drive the rotation of the corn, and high-pressure nozzles are arranged on the upper and lower sides of the roller. The upper and lower spraying method can be used to clean the surface of the corn in cooperation with the self-rotation of the corn, and the corn silk is knocked out by high pressure.

The washed corn silk and impurities will directly fall on the filter screen of the lower water tank. Use the double-layer interception of the filter to effectively filter out impurities. The cleaned water is filtered and then falls into the circulating water tank. Can guarantee the next cycle of use. Effectively save water.

Here is our sweet corn washign and air drying line working process in our facotry video for your reference!!

Sweet corn air drying machine

The air dryer have multiple turning and conveying, and has a reverse wind device to prevent dead spots from drying. The air dryer has a good drying effect and effectively removes water droplets on the surface of the material, which greatly shortens the preparation work for labeling and packing.

The whole material is stainless steel, which meets the food production safety standards; the fan with large air volume is adopted, the distance between each group of fans and the fan is appropriate, the air drying efficiency is high, and we can adjust the height of the fan freely according to different products.

Sweet vacuum packaging machine

The vacuum packaging machine eliminates part of the air (oxygen) in the packaging container, which can achieve the purposes of oxygen insulation, preservation, moisture-proof, mildew-proof, rust-proof, anti-corrosion, insect-proof, and anti-pollution, effectively prolonging the shelf life, preservation period, and convenient storage And transportation.

Reviews

There are no reviews yet.