Description

The mango pulp extraction machine is suitable for the separation of mango pulp residue after crushing and pre-cooking. One is coarse pulping, and the second is fine pulping. We can select the aperture of the two screens according to the requirements of the material.

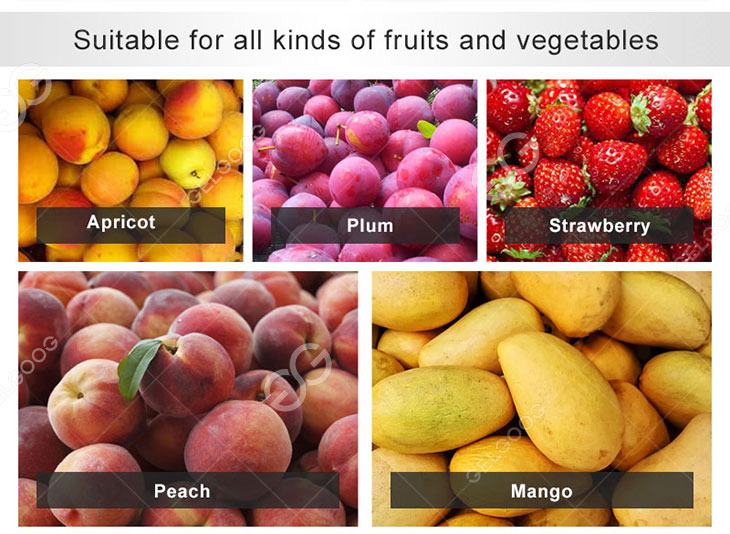

Mango pulper application

In addition to the extraction of mango pulp, it is also suitable for various pralines, berry pulp separation: stone fruits (mango, peach, apricot, etc.), berries (kiwi, strawberry) and pome (apple, pear) Etc.) beating and slag removal.

Mango Pulp Machinery Features:

Automatic separation of juice and residue (skin, seeds, nuts);

It has a wide range of applications and meets the requirements of most fruit and vegetable processing;

Single operation configurable hoist, simple, convenient, safe and reliable;

We can use it as a stand-alone machine or in the production line;

Different screens can be configured to obtain different processing effects;

The work efficiency is dozens of times that of manual work, and the fully automatic operation is truly realized, and the heavy body labor.

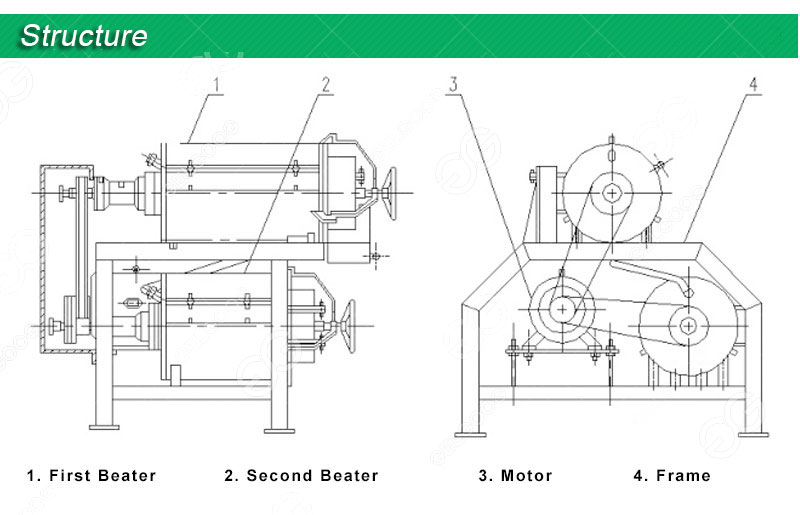

Fruit Pulp Extraction Machine Structure

A. Cylindrical screen: Use a stainless steel plate of 0.35~1.20mm thickness to pounch and bend the cylinder body into a circle

Weld after round, with reinforcement rings welded on both sides;

Or two semi-circular bodies are connected by screws to form a cylinder, which is installed horizontally inside the casing.

B. Shaft: It has two scrapers to move the material to the broken blade, screw propeller, and scrape the material;

The scraper connect with the holder on the shaft by bolts, and the adjustment bolt can adjust the distance between the scraper and the screen wall;

It is installed symmetrically on the side of shaft C, and has an included angle with the shaft warp-lead angle.

C. Lower hopper, collecting funnel, frame and transmission system.

Here is the toutube video of mango pulp machine working process for your reference!!

Mango Pulp Making Process

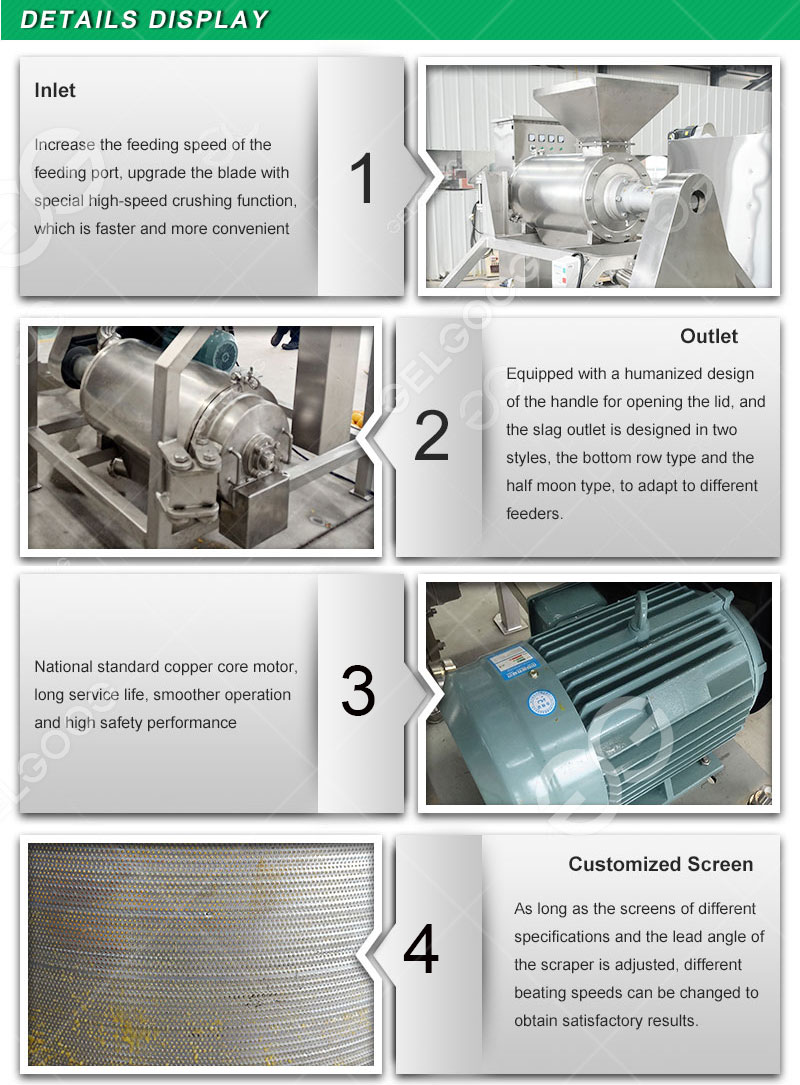

The scraper mounted on the spline shaft rotates through the V-belt driven by the motor to achieve high-speed rotation;

When the broken mango enters the machine through the feed port, the baffle plate will evenly discharge the material between the scraper and the screen;

The rotation effect of the scraper and the existence of the lead angle make the material move along the cylinder to the outlet end, and the moving track is spiral;

When the mango moves between the scraper and the screen by centrifugal force, the centrifugal force will crush the mango;

The mango slurry and meat pass through the screen holes into the next process, in order to achieve the purpose of automatic separation, the residue hopper will discharge the skins and seeds.

By changing screens of different specifications and adjusting the lead angle of the scraper, we can change different beating speeds and obtain satisfactory results.

Fruit Pulper Parameter

| Model | GG-1 |

| Capacity | 50-100kg/h |

| Power | 3KW |

| Voltage | 380v |

| Enucleated (peeled) Speed | 100-500r/min (frequency control) |

| Beating Speed | 860r/min |

| Beating mesh aperture | φ0.6-φ1.0mm |

| Dimension | 1350×770×1500mm |

Factors affecting the degree of crushing of the pulper material

(1) The nature of the material itself

(2) Sieve hole diameter: 0.4~1.5mm, different raw materials and processing requirements are different, we can change the sieve tube with different hole diameter.

(3) The percentage of the total area of the screen holes in the total area of the screen cylinder: 50%

(4) Lead angle 1.52.0 (with 3°)

(5) The distance between the stick and the inner wall: 1~4mm

(6) Rotation speed of shaft

Mainly adjust when using (6), (5), (4)

This machine has the characteristics of simple operation, convenient cleaning, safety and sanitation, continuous feeding, wide application range, etc. It is an ideal equipment for mango processing!

Reviews

There are no reviews yet.