Description

The chili sauce processing line can making hot sauce from 1T fresh chili per hour, which is a common condiment on the table. The chili sauce products made by fine processing have been greatly improved and improved in terms of spicy taste, nutritional content, consistency and color. The production technology and requirements are as follows:

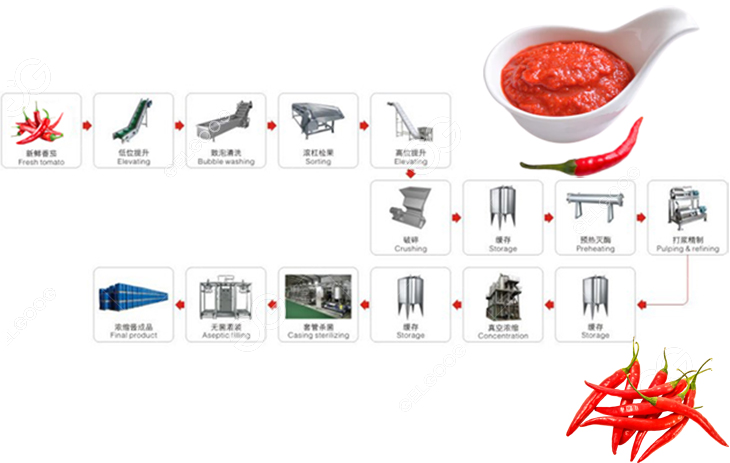

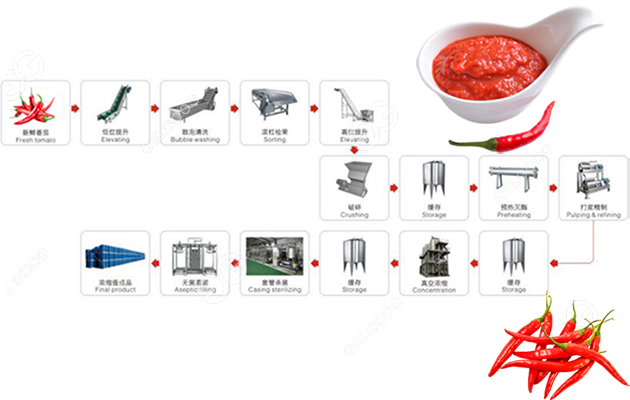

Fresh pepper→lifting→conveying and selecting→cleaning→draining→crushing→preheating→pulping→concentration→sterilization→vail aseptic filling processing process, each process corresponds to a specific pepper processing equipment:

Receiving: Fresh peppers delivery to the factory by truck and then transport to the unloading area. The water flow is used when unloading the peppers so that the peppers can be moved into the collection channel without being damaged.

Lifting machine: adopting a hoisting machine with a width of 0.8 mm, a lifting height of 1.4 meters, and a lifting belt made of PU material.

Conveyor picking belt: The staff removes peppers (MOT) and other materials other than green, damaged and discolored peppers. Place them on the waste conveyor and collect them in the storage unit to take them out.

Bubble cleaning machine: cleaning the pesticide residues and other debris on the surface of pepper;

Drum cleaning machine: This model has a large cleaning capacity and a high cleaning rate. The peppers are rotated 360 degrees to the vibration draining machine.

Vibration drain conveyor: made of all stainless steel, the vibration source is generated by the vibration exciter, so that the pepper is thrown on the screen, so as to play the role of vibration and drain

Hammer crusher: Uses high-speed rotating blades to crush peppers.

Preheater:The heating of the fruit pulp and the preheating of the fruit pulp can destroy the enzyme activity, prevent discoloration and pectin hydrolysis, dissolve the pectin in the pulp tissue, avoid the delamination of the pulp, and facilitate the processing of the next process

Double channel pulp making machine: Through the double-pass beater, the chili seeds are eliminated to obtain chili pulp;

Vacuum concentrator: It is the most energy-consuming step in the whole process-the excess water in the chili paste is extracted here, and the juice becomes a concentrated chili paste. The entire concentration/evaporation process takes place under vacuum conditions, and the temperature is significantly lower than 100°C.

Casing type sterilization machine: adopts a four-layer casing structure, in which the heat or refrigerant is distributed in two layers inside and outside, the chili sauce passes through the middle layer, and the chili sauce sterilizes evenly;

Single-head vat aseptic filling machine: Most facilities use aseptic bags to pack the finished product so that the chili sauce in the evaporator will not come into contact with the air before it contacts the customer.

Chili Paste Processing Line Advantage:

The chili sauce processing line is more compact and reasonable, saves floor space, and has a more streamlined appearance.

The hot pepper sauce production line is made of stainless steel in the contact part of the hot pepper, which ensures the safety and stability of production and meets the hygienic requirements.

The whole process from pepper processing to boxing and warehousing has been automated streamlining operations, which has changed the traditional workshop processing mode;

Reviews

There are no reviews yet.