Description

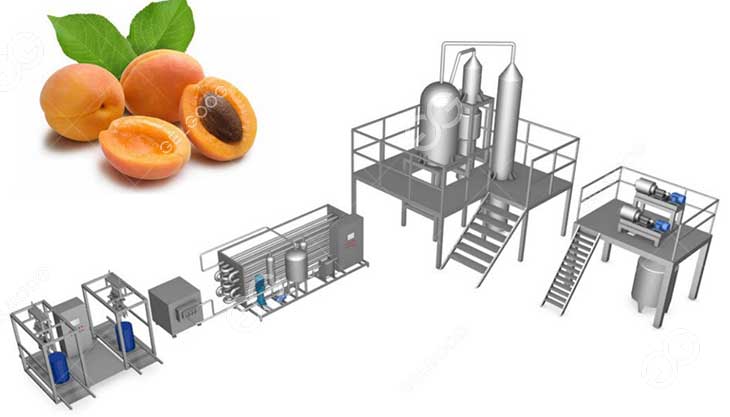

The jam production line mainly processes peaches, plums and apricots for cleaning, sorting, pre-cooking, de-pitting, beating, concentration, sterilization, and filling, and finally we can obtain the jam.

Each of the above processing procedures has a specific device corresponding to it:

Washing machine: It is mainly divided into two cleaning processes, using techniques such as bubble tumbling, brushing, and high-pressure spraying to clean peach, plum and apricot to the greatest extent.

Roller classifier: able to classify peach, plum and apricot according to different sizes;

Pre-cooking machine: After blanching, it can protect the unique fresh color of peach, plum and apricot, retain the fragrance, improve the softness of cells, and lay a good foundation for the process requirements of the next beating process.

Pulp making machine: Pulp making machine can automatically separate peach, plum, apricot slurry and residue, and it will automatically eliminate the core.

Colloid mill: In order to further refine the jam of peach, plum and apricot and increase the taste, it is necessary to use the colloid mill to finely grind the preliminarily obtained pulp of peach, plum and apricot;

Vacuum concentrator: remove excess water in peach, plum and apricot jam;

Sterilization machine: The casing type sterilization machine adopts a four-layer casing structure, which is specially used to sterilize various materials with poor fluidity and high viscosity, such as peach jam, plum jam and apricot jam.

Filling machine: aseptic vat filling machine is suitable for aseptic filling and filling of other viscous or non-viscous liquids, such as 1-1000L fruit and vegetable juice, jam and other concentrated products.

Advantages of jam system:

We can obtain the original color, fragrance and nutrition of peach, plum and apricot;

Stainless steel material ensures the cleanliness of peach, plum and apricot jam production;

Fully automatic operation process, saving manpower and material resources;

Filling in aseptic large barrels facilitates later transportation and extends the shelf life;

Features of jam production line:

Compact structure and beautiful appearance;

Support customization and provide turnkey projects according to customer needs;

One line is suitable for processing a variety of jams;

Reviews

There are no reviews yet.