Description

Our mango pulp processing machinery has a processing capacity of 2.5 ton mango per hour. It is filled in aseptic vats and is suitable for medium-scale mango pulp processing plants. This packaging method is not only convenient for transportation, but the shelf life can be extended to 1-2 years.

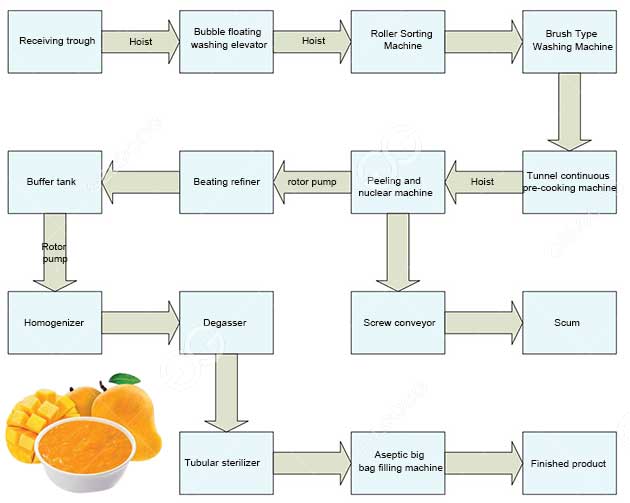

The complete set of mango pulp processing machinery includes: lifting, cleaning, picking, pre-cooking,de-pitting and beating, refining,homogenization, degassing, sterilization, and aseptic vat filling. Each step requires different mango processing machinery.

Lifting machine: It can lift fresh mango into the washing tank of the bubble washing machine;

Mango washing machine: This washing machine uses our self-developed bubble cleaning machine, which can clean the dirt on the mango skin. The cleaned mango is transported to the picking belt by the machine’s own elevator.

Roller type sorting machine: sorting mangoes, removing some immature small fruits and shrinking bad fruits;

Brush cleaning machine: The brush cleaning machine can clean the surface of mango more thoroughly;

Tunnel pre-cooking machine: It using steam as the heat source to pre-cook the mangoes, which has reached the completion and softening, which is convenient for subsequent pulping operations;

Mnago pulp making machine: The selected mangoes are peeled and cored by a beating and beating machine to obtain mango pulp;

Refined beater: mainly used for the separation of crushed or softened berries or pomace in a large mango paste factory.

Homogenizer: The obtained mango pulp is pumped into the homogenizer through a screw pump for homogenization treatment, which can make the mango pulp taste more delicate and more stable;

Vacuum deaerator: It is used to degas the homogenized mango pulp under vacuum to prevent oxidation of the mango pulp and extend the storage period of the pulp.

Sterilization machine: The casing type sterilization machine adopts a four-layer casing structure, which is specially used to sterilize various materials with poor fluidity and high viscosity such as jam, mango pulp, and maltodextrin.

Aseptic vat filling machine: Aseptic vat filling machine is suitable for aseptic filling and filling of other viscous or non-viscous fluids such as 1-1000L fruit and vegetable juice, mango pulp or its concentrated products, dairy products.

Mango Pulp Machinery Advantages:

Large production capacity, suitable for the production requirements of large and medium-sized mango pulp processing plants;

The pulp recovery rate is high, up to 99.5%;

Our important core-removing and beating machine integrates the function of core-removing, peeling and beating, and we must switch to purchase a special core-removing machine;

Support customization. According to your specific needs, I can provide you with a turnkey project for the mango pulp production line;

In the form of aseptic vat filling, foods filled by aseptic filling machines have a long shelf life and have a unique process. The taste, nutrition and color of the food are rarely affected;

Mango Processing Machine Characteristics:

The de-nuclear beating machine not only suitable for the production line ,but also suitable for alone;

The entire production line material is food-grade stainless steel to ensure the safety and health of the production process;

Fully automatic operation process, saving time and effort;

Mango pulp processing plants are crucial for mass production of mango pulp. We are a professional mango pulp processing equipment manaufacturer. Our mango processing plant adopts scientific design, sustainable stainless steel manufacturing, stable performance, convenient operation, and is widely applicable to various fruits. You can use our mango pulp machine to make high-quality mango pulp and get high profits. Contact us for more expertise on how to start the mango pulp industry.

Reviews

There are no reviews yet.